India, being traditionally an agrarian economy, with agriculture contributing 17.9% of the country’s GDP and employing over 50% of rural households, is the world’s 2nd largest producer of fruits and vegetables. However, despite an estimated annual production capacity of 269 Million MT of fruits and vegetables, only 2% of the produce is processed and approximately 5-16% of the produce is lost along the cold chain. Predominantly caused due to poor post-harvest management, inadequate logistics and inefficient storage, this food loss is estimated to be approximately USD 14 billion. This loss of food directly impacts the revenues of the Indian farmer thus making him earn less out of his produce.

Within India, Punjab is one of the most fertile regions, and is often known as the bread-basket of India. While the total area of the state is only 1.5% of the total area of India, it produces 12% of the cereals produced in the country. However, the farmers in Punjab, whilst enterprising, have not been able to realize the fullest potential of their produce. Lack of cold chain infrastructure has made them settle for lower prices for their produce locally, as well as disable them to send their produce to international markets due to low shelf life. Additionally, they can’t arrest the huge loss of the produce either due to lack of cold stores and processing infrastructure, resulting in further losses.

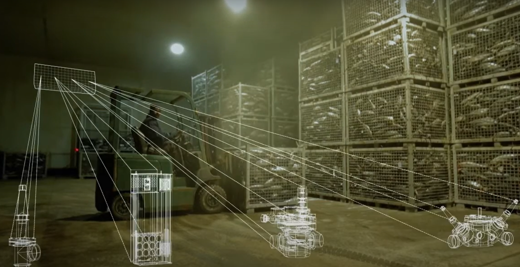

In this scenario, an energy-efficient cold chain infrastructure from the point of harvest to the point of consumption becomes a crucial and game-changing solution for farmers. Advanced technologies for cold storage can help enhance the shelf life and quality of their harvest, incentivize higher agricultural production, help farmers to directly expand their selling radius by connecting with more distant markets and thus boost their incomes.

One such organization that is transforming the lives of farmers is Pagro Foods Limited in Punjab. Pagro Foods, a leading supplier of frozen vegetables in South East Asia, has been working with over 900 farmers and has been carrying out contract farming across over 4000 acres of land. Pagro Foods has helped improve the shelf life of the farmers’ produce and thus maximize their earnings on the back of an efficient Individual Quick Freezers (IQF) processing facility and a robust cold storage system with smart temperature control. Pagro Foods has further enabled the farmers to sell their produce to leading retail brands such as Godrej, McDonald’s and McCain Foods.

Pagro Foods’ efficient cold chain infrastructure has been powered by the global leader in refrigeration technology, Danfoss. With 85 years of engineering excellence, Danfoss has been innovating to enhance the efficiency of the cold chain infrastructure in India and reduce farm-to-fork food losses. At Danfoss, we believe in engineering the food supply for tomorrow and we take pride in partnering with Pagro Foods in transforming the lives of many farmers. Through precision in temperature control for the IQF and cold stores, Danfoss solutions helped sustain the food quality and improve the shelf life of the farmer’s produce. Further, Danfoss’ cold chain technology helped make the refrigeration systems at Pagro Foods versatile thus helping save energy of up to 20% which further adds to the farmer’s profitability.

With a portfolio spanning across ammonia and freon refrigeration solutions and encompassing traditional as well as oil-free technologies, Danfoss provides customers with the flexibility to design or redesign their cold chain infrastructure to suit their requirements. With futuristic and energy efficient technologies for cold chain systems, Danfoss is enabling India to make high quality food available for its growing population and help farmers double their income, thereby catapulting India onto the global league of food producers.