Energy efficient pumps for desalination

With Danfoss high-pressure APP pumps tailored to Sea Water Reverse osmosis (SWRO) applications you will get one of the most reliable and sustainable pumps for desalination. The APP pumps can be used in almost any SWRO application – land-based, offshore or marine. Mounted in containers or trains, the APP pumps can contain several pumps in parallel to secure uninterrupted and sufficient supply at any time.

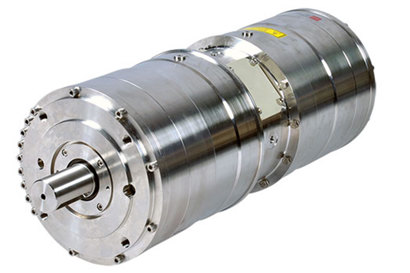

Danfoss has pioneered axial piston pump technology in challenging hydraulic applications for several years. With more than 15 patents, a strong precision engineering heritage and world-class production know-how in Duplex, Super Duplex and carbon-reinforced PEEK, Danfoss designs and produces the most advanced high-pressure pumps available for reverse osmosis. The APP pump is oil-free, using only water for lubrication. Most pumps can be delivered with ATEX and API 674 approvals.

The Danfoss APP pumps are available in various sizes from 0.6 m3/h to 92 m3/h for use in small and medium-sized SWRO facilities.

Features and benefits

Extensive application know-how

Highest efficiency rates in the industry

Compact and small – half size of competing pumps

Long time between service intervals

Easy and service-friendly design

Simple and reliable with high uptime

Short pay-back time

Make fresh water in a sustainable and energy-efficient way

Reduce energy costs by applying the Danfoss APP pump

Compact and simple design

Due to its high energy-efficiency and reliability, SWRO has turned into one of the most sustainable and cost effective desalination solutions for land-based, offshore and marine applications. The technology is reliable and safe with high-pressure pumps forcing seawater through desalination membranes to create fresh water. Danfoss supplies expertise and unique technologies that can offer your business high efficiency, low maintenance and flexible configuration.

Product range

-

if (isSmallPicture) {

APP 53-86 high pressure pump

APP 53-86 high pressure pumpPressure range: Max outlet pressure: 80 barg/1,160 psig

Min. outlet pressure, inlet: 2-5 barg/ 29-72.5 psig

Flow range: 24-88 m3/h - 106-387 gpm

Speed: 700 to 1,700 rpm -

if (isSmallPicture) {

APP 21-43 high pressure pump

APP 21-43 high pressure pumpPressure range: Max outlet pressure: 80 barg/1,160 psig

Min. outlet pressure, inlet: 2-5 barg/29-72.5 psig

Flow range: 12.3-44.9 m3/h - 54.2-197.6 gpm

Speed: 700 to 1,700 rpm -

if (isSmallPicture) {

APP 11-13 high pressure pump

APP 11-13 high pressure pumpPressure range: Max outlet pressure: 80 barg/1,160 psig

Min. outlet pressure, inlet: 0.5-5 barg/7.3-72.5 psig

Flow range: 9.2-13.8 m3/h - 40.5-60.8 gpm

Speed: 700 to 1,500 rpm -

if (isSmallPicture) {

APP 0.6-1.5 high pressure pump

APP 0.6-1.5 high pressure pumpPressure range: Max outlet pressure: 80 barg/1,160 psig

Min. outlet pressure, inlet: 0.5-5 barg/7.3-72.5 psig

Flow range: 0.2-1.3 m3/h - 0.9-5.7 gpm

Speed: 700 to 3,450 rpm -

if (isSmallPicture) {

APP 16-22 high pressure pump

APP 16-22 high pressure pumpPressure range: Max outlet pressure: 80 barg/1,160 psig

Min. outlet pressure, inlet: 2-5 barg/29-72.5 psig

Flow range: 13,3-21,9 m3/h - 58.6-96.4 gpm

Speed: 700 to 1,500 rpm

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|

Related products

-

if (isSmallPicture) {

DST P40I titanium pressure transmitter for harsh environments

DST P40I titanium pressure transmitter for harsh environmentsFor use in corrosive environments, Danfoss offers the new robust DST P40I pressure transmitter made of Titanium and with ceramic pressure sensing element. DST P40I is optimized for use in applications such as desalination systems, seawater cooling, and chemical processing.

-

if (isSmallPicture) {

High-pressure pumps for ZLD reverse osmosis applications

High-pressure pumps for ZLD reverse osmosis applicationsThe APP W HC pump is suitable for ZLD reverse osmosis applications used in industrial wastewater treatment.

-

if (isSmallPicture) {

iSave® energy recovery devices for high-pressure membrane applications

iSave® energy recovery devices for high-pressure membrane applicationsThe 3-in-1 Energy Recovery Device (ERD) optimized for sea water reverse osmosis applications.

-

if (isSmallPicture) {

VLT® AQUA Drive FC 202

VLT® AQUA Drive FC 202VLT® AQUA Drive FC 202 controls all types of pumps and comes equipped with a cascade controller.

Related solutions

How it works

Case studies

Reverse osmosis case studies

Learn more where to use our APP pumps and iSave ERDs in reverse osmosis applications

Learning

Pump animation

Learn how an axial piston pump works in this video animation

Articles

Coming soon...

Coming soon...