Danfoss offers a range of oil nozzles in both brass and steel for standard burner systems. We provide series of special nozzles which are adapted to operating area, media and emission to suit different markets.

We produce nozzles in accordance with EN 293 and EN 299. To ensure quality results, each nozzle is tested 100% electronically for capacity and spray pattern.

To avoid risks and to perform at its best, an oil burner needs the same attention as your car. Regular inspection and servicing are essential to ensure that it is running reliably and at optimum efficiency. Danfoss recommends changing the nozzle once a year for the benefit of the environment and operating performance.

Features and benefits

A well-adjusted burner can reduce oil consumption by as much as 10%. Keeping it free from soot can achieve even greater savings.

Danfoss recommends to change the nozzle once a year out of consideration for environment and operating performance.

Have you changed oil nozzle this year?

See the instructions for a safe and optimal change of a Danfoss oil nozzle on an oil burner.

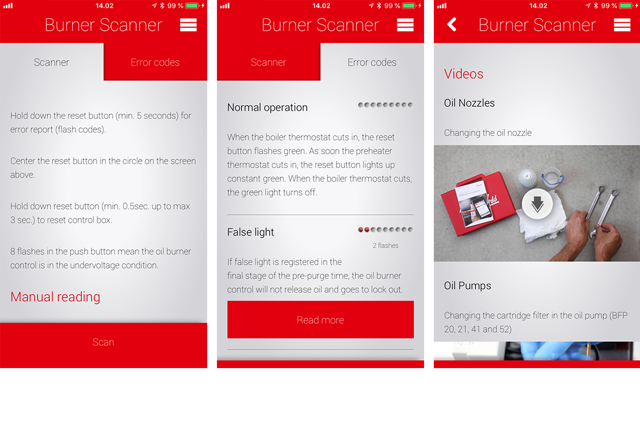

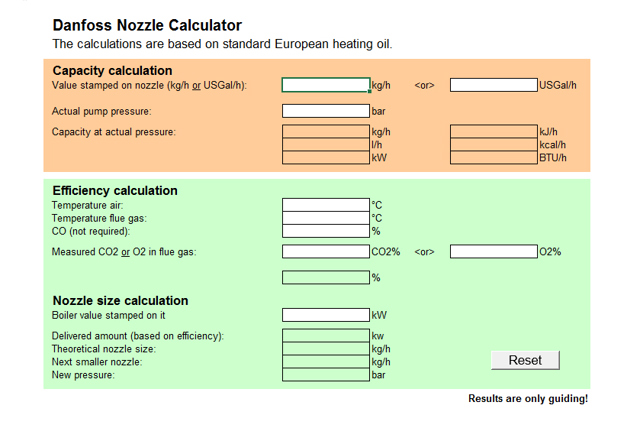

Tools and apps

Software tools