Balancing energy in municipal and industrial wastewater treatment

Since water and wastewater treatment processes account for 4% of global electricity consumption, it's vital that reducing energy consumption is in focus for industrial and domestic wastewater treatment. Not only for sustainability but also for economic reasons.

Transformation of municipal wastewater treatment plants from energy consumers into energy generators now couples the water and energy sectors together into a new game-changing industry. Regulation of rotating equipment is a vital element in generating over 100% surplus power in wastewater treatment, for energy-neutral water cycle management of entire communities.

Substantial amounts of fresh water are consumed in modern society and all too often poorly treated wastewater is discharged into the environment. To counter these trends, modern digitalization offers a great degree of controllability in municipal wastewater treatment resulting in higher quality of treated water. And ZLD and MLD processes reduce the volume of industrial wastewater discharge.

To improve the reuse of water and reduce the discharge of industrial wastewater, a zero liquid discharge (ZLD) or a minimal liquid discharge (MLD) treatment system is often used. ZLD and MLD are ambitious wastewater management strategies that enable the plant or facility to recover most of its wastewater for reuse. The standard process is energy intensive, but applying optimized reverse osmosis processes energy consumption can be reduced by up to 75%.

Wastewater treatment plants

Typically, water and wastewater treatment processes account for 25-40% of a municipal electricity budget. Water and wastewater facilities are therefore normally the single-largest electricity consumer for a municipality. Therefore for many years, extensive use of AC drives and real-time online sensors have created the basis for advanced real-time process control to optimize energy efficiency, cutting energy consumption by 20–40%.

Now these methods combine with energy production within the wastewater treatment plant, to enable entirely new ambitious levels of energy efficiency. Powered by methane produced in the digester of the wastewater plant, the 'bio refinery' or 'Water Resource Recovery Facilities' demonstrate that wastewater has now become an energy resource.

Some of the most advanced water management systems achieve complete energy self-sufficiency of the water cycle. The energy recovered from wastewater treatment process not only covers the plant's own needs, but also the energy needs for drinking water production and distribution as well as wastewater pumping. In other words, the whole water cycle can be considered energy neutral.

A precondition for energy neutrality is a control handle in the form of an AC drive available for all rotating equipment, so that the fully computer-controlled facility can adapt to the changing load.

Generating surplus power from wastewater treatment

Since 2010, Marselisborg wastewater treatment plant has transformed its focus beyond minimizing energy consumed, to maximizing net energy surplus. Nowadays the facility has net production of both electricity and heat, supplying the district heating system in Denmark’s second-largest municipality, Aarhus. The carbon footprint has been reduced by at least 35% accordingly.

Tackling water scarcity with efficient ZLD and MLD water treatment

To improve the reuse of water and reduce the discharge of industrial wastewater, Zero Liquid Discharge (ZLD) and Minimal Liquid Discharge (MLD) have emerged as highly efficient wastewater treatment processes.

ZLD and MLD are ambitious wastewater management strategies, which eliminate/reduce any liquid waste leaving the plant or facility with most water being recovered for reuse.

The efficient reduction of effluent makes the ZLD and MLD processes highly attractive to industries and utilities. Until now, however, the processes have been constrained by high costs and intensive energy consumption. The traditional thermal-based process used in ZLD/MLD systems is highly energy intensive. By adding a membrane-based process, studies show that energy consumption can be reduced by up to 75%.

ZLD and MLD reverse osmosis applications

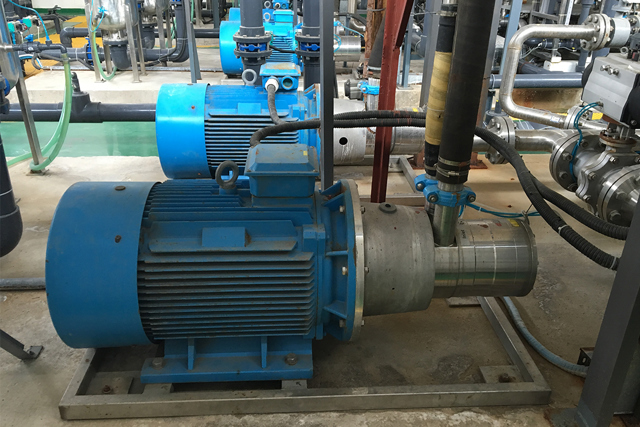

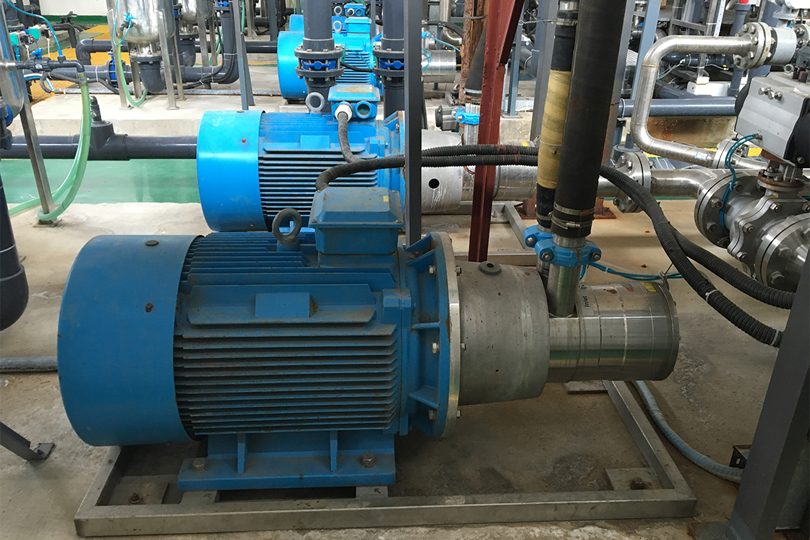

Learn more about how to use our APP W HC pumps in ZLD reverse osmosis applications

Stormwater overflow

Optimization of the wastewater canalization system using pump regulation can improve pump efficiency by 15–30% and also drastically reduce maintenance costs in managing stormwater overflow.

The traditional solution for combined sewer systems to limit storm water overflow, is to build major storage tanks on the sewer network, which then can store the high volume of water arising with heavy rain.

Using digitization, and connected to a high-granularity weather radar system, highly accurate rainfall analysis can be integrated. By managing capacity optimally, the utility can reduce capital investment. Digitization also enables them to operate a warning system, in the rare event that a sewer overflow does occur.

Related products

-

if (isSmallPicture) {

APP pumps

APP pumpsThe APP pumps are designed for SWRO in land-based and marine applications, offering the highest efficiency rates in the industry. The compact design, long service intervals and reliability of the APP makes it a first choice for small and medium-sized desalination plants.

-

if (isSmallPicture) {

iSave® energy recovery devices for high-pressure membrane applications

iSave® energy recovery devices for high-pressure membrane applicationsThe 3-in-1 Energy Recovery Device (ERD) optimized for sea water reverse osmosis applications.

-

if (isSmallPicture) {

High-pressure pumps for ZLD reverse osmosis applications

High-pressure pumps for ZLD reverse osmosis applicationsThe APP W HC pump is suitable for ZLD reverse osmosis applications used in industrial wastewater treatment.

-

if (isSmallPicture) {

VLT® AQUA Drive FC 202

VLT® AQUA Drive FC 202VLT® AQUA Drive FC 202 controls all types of pumps and comes equipped with a cascade controller.

Case studies

Related applications

Learning

Save energy with a membrane-based process

Most ZLD/MLD systems are operated with a thermal-based process as standard. This process puts a great demand on energy consumption, making it a very expensive investment.

One way of reducing energy consumption is to reduce the amount of water that needs to be evaporated by changing from a thermal to a membrane-based process. This is supported by studies that show an efficiency gain of up to 75% when going from the thermal-based to the membrane-based process.

How business benefit from applying a ZLD or MLD treatment system

Zero or minimal liquid discharge are some of the good answers to the global water crisis. Both technologies help to meet discharge and water reuse requirements enabling businesses to meet regulations, protect the environment and improve management of the water produced.

Rethinking the water sector

Energy generation and water management are intricately entwined. Today, technologies designed to create an energy-neutral water sector are already available.