About inverter technology for AC, heating and ventilation

A quantum leap in energy efficiency

The HVAC market is rapidly changing. Inverter technology is the most energy efficient technology and is currently revolutionizing the way air conditioning systems are being designed and built to meet climate control needs around the world. The first to embrace variable-speed technology gains a competitive advantage.

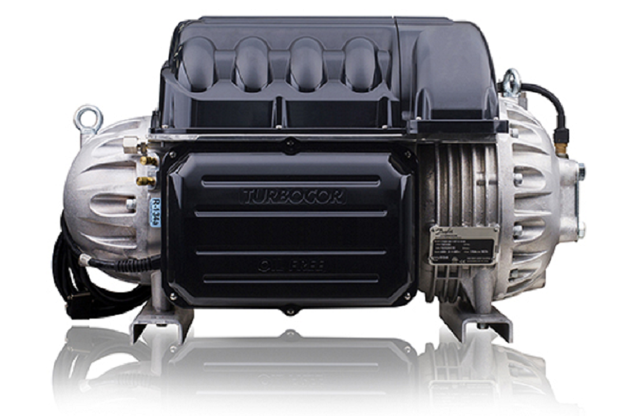

Market needs: Avoid system oversizing, reduce electricity bill and inrush current, increased comfort and process are some key drivers for variable capacity.

Modulating technologies: There are several ways to modulate the cooling capacity in refrigeration or air conditioning and heating systems.

Working principle: Inverter compressors operate at different speeds generating a modulated refrigerant mass oil flow and cooling output.

Video "Inverter Compressors for HVAC"

Benefits: Better power supply quality, system diagnostics, humidity control, energy savings, accurate temperature control, less noise, process safety, greater comfort

Challenges: Compressor and drive selection, designer skills makes the system overall reliability and efficiency.

Danfoss variable speed technology

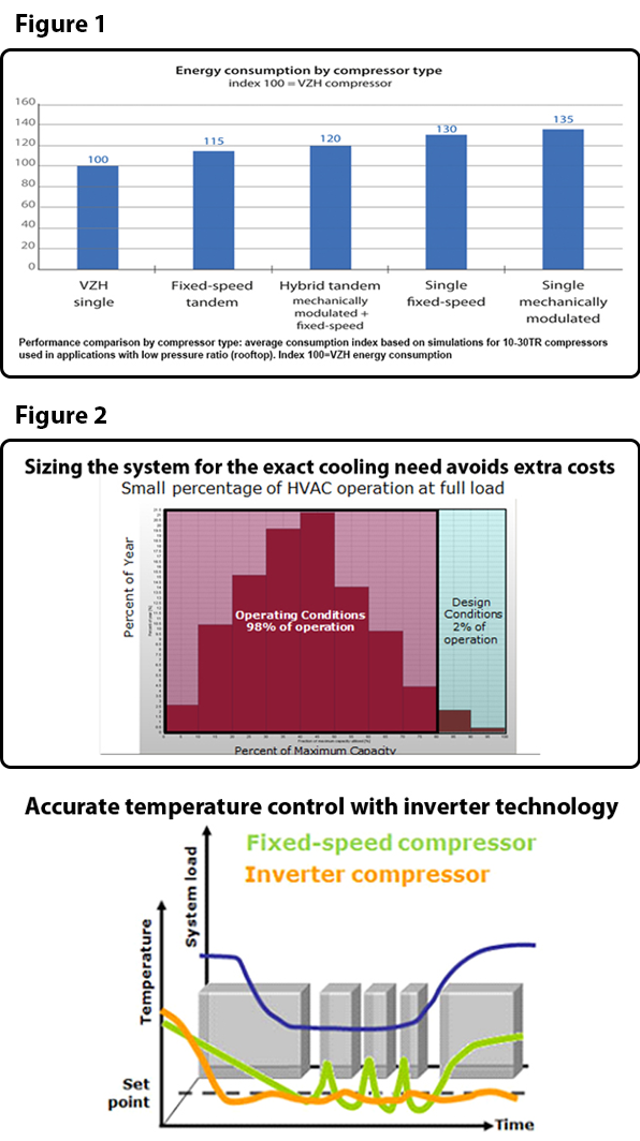

By using the Danfoss inverter compressor solutions, significant energy savings can be achieved compared to traditional on-off compressors or mechanically-modulated technologies.

Highlighted products

-

if (isSmallPicture) {

Inverter scrolls - VZH

Inverter scrolls - VZHDanfoss inverter scroll compressor VZH offers effectiveness and reliability. Over 30% energy savings is possible in rooftops, chillers, close controls etc.

-

if (isSmallPicture) {

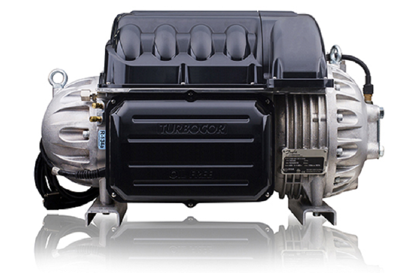

Turbocor® - TT

Turbocor® - TTDanfoss Turbocor® model TT oil free compressors are available in four different models ranging from 60 tons to 200 tons / 200 to 700 kW utilizing R134a or non-flammable, low GWP R513A.

-

if (isSmallPicture) {

Turbocor® - TG

Turbocor® - TGDanfoss Turbocor® model TG oil free compressors are available in four different models ranging from 40 tons to 150 tons / 140 kW to 540kW utilizing ultra-low GWP HFO1234ze.

-

if (isSmallPicture) {

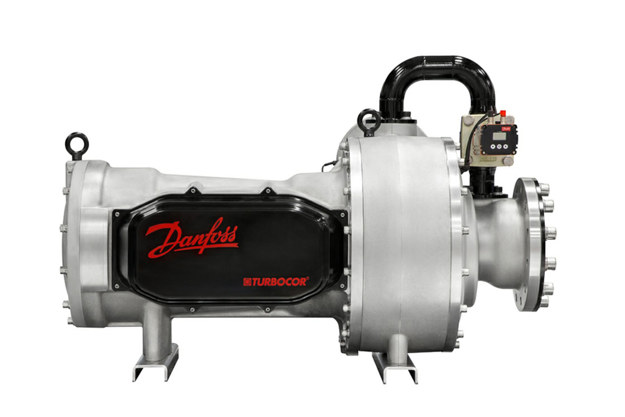

Turbocor® - VTT

Turbocor® - VTTDanfoss Turbocor® model VTT oil free compressor is available with a capacity up to 400 tons / 1430 kW using R134a. This compressor is designed for water and evaporative cooled chiller applications.

-

if (isSmallPicture) {

Turbocor®

Turbocor®Danfoss is the leading manufacturer of oil free compressors and is the pioneer of the Danfoss Turbocor® compressor - the world’s first oil-free magnetic bearing compressor for the HVAC industry.

Related applications

-

if (isSmallPicture) {

Air handling units with inverter

Air handling units with inverterAir handling units with integrated cooling are used in commercial applications for air conditioning in many different kinds of buildings, from small office buildings, fitness centers and medical institutions to skyscrapers.

-

if (isSmallPicture) {

Close controls with inverter

Close controls with inverterPackaged unit for electronic cabinet cooling.Close control air conditioners are used in the cooling of electronics such as IT and electronic equipment used in data centres, in telecommunications and in manufacturing industries.

-

if (isSmallPicture) {

Modular chillers

Modular chillersCore component of the HVAC system, a chiller cools the water or brine used to cool and dehumidify air in buildings or industrial processes. It's a factory-assembled unit that cools the water or brine using an evaporator, and has an internal or a remote condenser with appropriate controls.

-

if (isSmallPicture) {

Packaged unit

Packaged unitCooling of IT equipment in data centres is an increasing challenge for operators and design engineers. Power management is the major challenge, with energy consumption and heat loads increasing in step with the server density. Meeting these challenges is essential for ensuring the safety and availability of the data.

Learning

Online training and e-lesson about inverter technology

Welcome to the Danfoss online training portal! Through this service, Danfoss strengthens its support to all HVAC-R professionals and students. Sign-up today for a great opportunity to maximize your performances and profits!

What’s in it for me?

- Learn about the existing technology from the leader in variable speed / inverter compressors.

- We offer free e-lessons, online courses and face-to-face seminars illustrated with technical explanations, videos and in field experiences.

Just follow these quick steps to start:

- Register on Danfoss learning Platform.

- Attend the e-lessons by clicking on below links

Case studies

-

if (isSmallPicture) {

Delivering Smart Indoor Comfort to the world’s 1st Solar Powered Airport

Delivering Smart Indoor Comfort to the world’s 1st Solar Powered AirportAirports globally have evolved from just being docking stations for the flights to becoming an avenue that houses the best experiences a traveler can get. From retail stores to restaurants, from lounges to culture showcase centers, every new airport today is pushing the standard on experiences. But, delivering these uber experiences alongside a thermal comfort inside the airport expends a lot of energy. With close to 100 million passengers travelling through domestic routes every day in India[1] and with the number exponentially increasing, curating a comfortable experience for the guests can be a challenge.

-

if (isSmallPicture) {

Driving the Metropolis with an Energy-Efficient Metro

Driving the Metropolis with an Energy-Efficient MetroDanfoss offered its energy efficient solutions to Delhi Metro to save energy without compromising on the indoor comfort and convenience of its commuters and is committed to doing so in future. Driven by a deep application expertise and future-facing technologies, Danfoss is poised to support the metro to be energy-efficient and to yield high performance, and thereby engineering tomorrow’s India, today.

-

if (isSmallPicture) {

Engineering the precise indoor comfort for the better movie experience

Engineering the precise indoor comfort for the better movie experienceLearn how Danfoss offered a solution for a plug-and-play, maintenance-free HVAC system which is convenient and efficient, and delivers precise temperatures, helping PVR deliver a truly world-class movie-watching experience to its customers.

-

if (isSmallPicture) {

Denmark's new climate-friendly hospitality giant depends on Turbocor® oil-free chiller

Denmark's new climate-friendly hospitality giant depends on Turbocor® oil-free chillerThe new Alsik hotel in Southern Denmark sets a higher standard in energy-efficiency and is built to reach 76% CO₂-neutrality. A main contributor is the 900-kW chillers by Clint (a company of G.I. Industrial Holding) which features award-winning Danfoss Turbocor oil-free compressors.

-

if (isSmallPicture) {

Oil-free compressors maintain consistent performance over time

Oil-free compressors maintain consistent performance over timeDanfoss conducted a study to see how long term operation affected performance on Danfoss Turbocor® compressors. The results showed that oil-free, magnetic bearing compressors maintained consistent performance even after 10+ years of operation.

-

if (isSmallPicture) {

Wind power

Wind powerWind turbine producing water cooled by an energy efficient refrigeration system featuring inverter scroll compressor

News

-

if (isSmallPicture) {

New 8.5 TR and 11 TR variable speed compressors with IDVWednesday, 10 October, 2018

New 8.5 TR and 11 TR variable speed compressors with IDVWednesday, 10 October, 2018 -

if (isSmallPicture) {

New extension of Danfoss ATEX Lab accelerates the use of sustainable refrigerantsFriday, 21 September, 2018

New extension of Danfoss ATEX Lab accelerates the use of sustainable refrigerantsFriday, 21 September, 2018With 100 customers, journalists, and employees in attendance, the ribbon was cut and the doors to our newly extended ATEX lab were opened yesterday. This facility will speed up the testing of refrigerant options for compressors, easing the transition to more sustainable refrigerants.

-

if (isSmallPicture) {

VLT® HVAC Drive joins exclusive company of 1000 Efficient Solutions globallyTuesday, 17 July, 2018

VLT® HVAC Drive joins exclusive company of 1000 Efficient Solutions globallyTuesday, 17 July, 2018How does reduction of methane production in beef cattle and the transformation of biogas into clean fuel for heavy vehicles link to efficient buildings enabled by Danfoss? They are all endorsed by the World Alliance for Efficient Solutions.

Contact us

For further information, please contact us.