Precision cooling with inverter technology

Application description

In many industrial processes the machinery or processes generate heat which requires cooling, to protect the equipment and/or to ensure that the product being manufactured is of the required quality. The process cooling unit is used to cool, to extract humidity or regulate the temperature of the manufacturing process.

A good example of this need for cooling during manufacturing is found in the plastics industry, where injection machinery heats the plastic polymer to enable it to be moulded or extruded. In the blow moulding of plastic films, the temperature control of the extruded film is important, since this affects the quality and thickness of the film.

Cooling equipment can be of different types, depending on whether air or liquid is the cooling medium which needs precise temperature control. The cooling equipment often needs to be very flexible in order to allow industrial machinery to use the same cooling equipment in different processes. For example, a plastic film blow-moulding machine can produce thin films; then the temperature set point needs to be relatively high (typically 20°C). The same machine can also produce thicker plastic films, but then the temperature set point needs to be lower.

In addition to the need to be able to maintain different temperature set points during a manufacturing process, process coolers have to be able to maintain a stable temperature at the set point despite variation in the ambient temperature.

Why choose Danfoss variable speed compressors for process cooling?

By using the Danfoss inverter compressor – a reliable compressor combined with a prequalified drive – the challenges involved in manufacturing applications like the above can be met.

Variable speed solutions adapt very quickly to cooling demand and keep the process at a precise set point (±0.2°C) despite varying ambient temperatures. If process parameters need to be changed, smooth and very precise temperature control is possible, as shown below in a comparison between close control using inverter compressors and using traditional on-off compressor technology.

In addition to precision temperature control, variable speed compressor solutions will be more energy efficient compared to traditional on-off compressor technology, especially when running in part-load conditions.

What are the benefits for your customers when they choose Danfoss inverter compressors?

- The compressors can maintain stable and precise temperatures, improving process and equipment reliability

- Down time costs are reduced

- Part-load operation increases the overall efficiency of the system

- Start-up current requirement is low

- There are significant energy savings

The most important benefits for customers

- Precise temperature control achievable within ±0.2°C , improving processes, quality of products and equipment lifetime

Additional benefits

- Innovation and development of new technologies made possible.

- Increased market share achievable through more innovative products

- Greater ability to expand and grow.

Products

-

if (isSmallPicture) {

Inverter scrolls - VZH

Inverter scrolls - VZHDanfoss inverter scroll compressor VZH offers effectiveness and reliability. Over 30% energy savings is possible in rooftops, chillers, close controls etc.

-

if (isSmallPicture) {

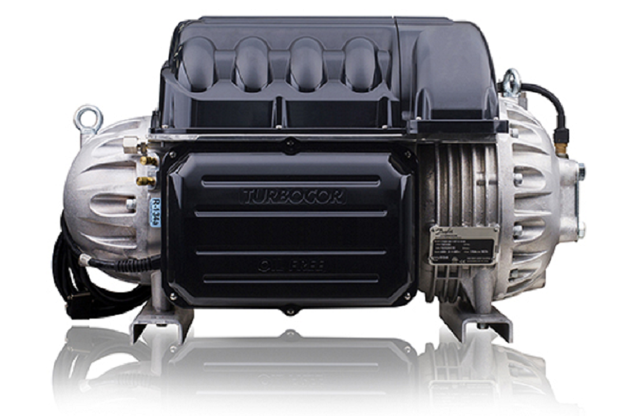

Turbocor® - TG

Turbocor® - TGDanfoss Turbocor® model TG oil free compressors are available in four different models ranging from 40 tons to 150 tons / 140 kW to 540kW utilizing ultra-low GWP HFO1234ze.

-

if (isSmallPicture) {

Reciprocating inverter - VTZ

Reciprocating inverter - VTZDanfoss reciprocating inverter compressors avoid oversized and short cycling systems. The compressor automatically adapts to the current load. By combining an efficient Danfoss Maneurop® reciprocating compressor with a Danfoss Drive, the company provides an innovative and intelligent package that utilizes variable-speed technology to ensure superior efficiency across the entire operating range for precision cooling.

-

if (isSmallPicture) {

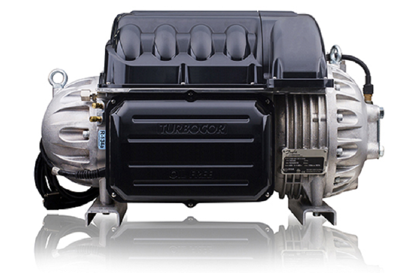

Turbocor® - TT

Turbocor® - TTDanfoss Turbocor® model TT oil free compressors are available in four different models ranging from 60 tons to 200 tons / 200 to 700 kW utilizing R134a or non-flammable, low GWP R513A.

-

if (isSmallPicture) {

Inverter scrolls - VRJ

Inverter scrolls - VRJDanfoss inverter scroll compressor solutions for commercial air conditioning and process-cooling applications. R410A, single units. VSH: first-generation commercial inverter scroll compressors with frequency converter CDS302. VZH: second-generation commercial inverter scroll compressors with frequency converter CDS303. VRJ: first high-tier residential inverter scroll compressors with frequency converter CDS801.

Case studies

-

if (isSmallPicture) {

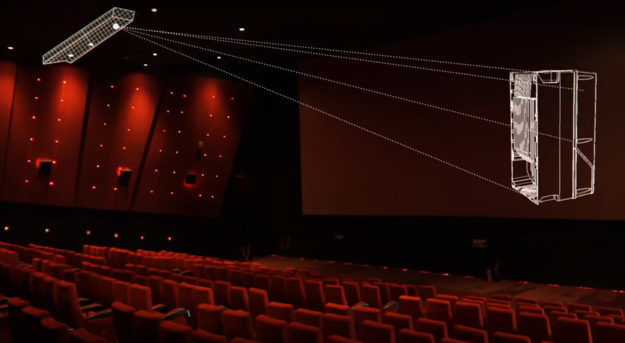

Engineering the precise indoor comfort for the better movie experience

Engineering the precise indoor comfort for the better movie experienceLearn how Danfoss offered a solution for a plug-and-play, maintenance-free HVAC system which is convenient and efficient, and delivers precise temperatures, helping PVR deliver a truly world-class movie-watching experience to its customers.

-

if (isSmallPicture) {

Delivering Smart Indoor Comfort to the world’s 1st Solar Powered Airport

Delivering Smart Indoor Comfort to the world’s 1st Solar Powered AirportAirports globally have evolved from just being docking stations for the flights to becoming an avenue that houses the best experiences a traveler can get. From retail stores to restaurants, from lounges to culture showcase centers, every new airport today is pushing the standard on experiences. But, delivering these uber experiences alongside a thermal comfort inside the airport expends a lot of energy. With close to 100 million passengers travelling through domestic routes every day in India[1] and with the number exponentially increasing, curating a comfortable experience for the guests can be a challenge.

-

if (isSmallPicture) {

Driving the Metropolis with an Energy-Efficient Metro

Driving the Metropolis with an Energy-Efficient MetroDanfoss offered its energy efficient solutions to Delhi Metro to save energy without compromising on the indoor comfort and convenience of its commuters and is committed to doing so in future. Driven by a deep application expertise and future-facing technologies, Danfoss is poised to support the metro to be energy-efficient and to yield high performance, and thereby engineering tomorrow’s India, today.

-

if (isSmallPicture) {

Denmark's new climate-friendly hospitality giant depends on Turbocor® oil-free chiller

Denmark's new climate-friendly hospitality giant depends on Turbocor® oil-free chillerThe new Alsik hotel in Southern Denmark sets a higher standard in energy-efficiency and is built to reach 76% CO₂-neutrality. A main contributor is the 900-kW chillers by Clint (a company of G.I. Industrial Holding) which features award-winning Danfoss Turbocor oil-free compressors.

-

if (isSmallPicture) {

Oil-free compressors maintain consistent performance over time

Oil-free compressors maintain consistent performance over timeDanfoss conducted a study to see how long term operation affected performance on Danfoss Turbocor® compressors. The results showed that oil-free, magnetic bearing compressors maintained consistent performance even after 10+ years of operation.

-

if (isSmallPicture) {

Wind power

Wind powerWind turbine producing water cooled by an energy efficient refrigeration system featuring inverter scroll compressor

Contact us

For further information, please contact us.