Case and cold room solutions

Accurate temperature and operation control of display cases and cold rooms are vital for high-quality and safe food products. You have several options to achieve optimum operating conditions of display cases and cold rooms. You can choose either remote control, i.e. connected to a separate compressor rack/pack and condenser, or you can opt for a self-contained unit, where the entire system including compressor and condenser is housed in the unit.

No matter what solution you prefer, Danfoss provides all you need in terms of components and application expertise.

Features and benefits

Innovative solutions to improve energy efficiency

Low installation and operating costs thanks to long lifetime components and advanced communications capabilities

Unsurpassed expertise with natural refrigerants to achieve safe and efficient solutions

Field- and electronically-delivered services partnering with end-users to deliver projects that save energy and maintenance costs

Food safety through controllers equipped with HACCP reporting capabilities to track and improve performance

The full range of Evaporator Controls from ADAP-KOOL®

ADAP-KOOL® case controllers offer highly efficient adaptive routines for each cabinet and cold room installation guaranteeing significant energy savings and early warning alarms to avoid potential food loss.

Related products

-

if (isSmallPicture) {

Micro Plate™ technology

Micro Plate™ technologyThe next step in application-focused, high-performance heat exchanger

design, Micro Plates™ are a revolutionary technology, specially created for

district energy solutions and for use in heat pumps, chillers, and close control

systems for cooling capacities up 800 kW / 225 TR. -

if (isSmallPicture) {

Sight glasses

Sight glassesSGP is a series of sight glasses for high pressure applications (Max Working Pressure 52 bar/754 psig). SGP is available in versions optimized for refrigerants with mineral oil e.g. HCFC, and in versions optimized for non-flammable HFC refrigerants. SGP is available with flare, solder and socket connections, and with and without moisture indicators.

-

if (isSmallPicture) {

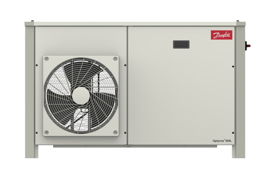

Condensing units

Condensing unitsOptymaTM ranges of condensing units match your commercial refrigeration application needs, with their unique versatility and simplicity to install. Multi-refrigerants, using low-GWP and natural refrigerants, highly efficient, they are a perfect fit for small to mid-size cold rooms, display cabinets, milk cooling tanks, fermentation rooms and much more.

-

if (isSmallPicture) {

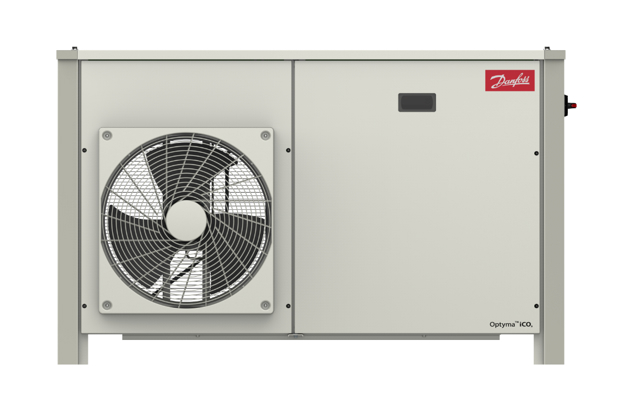

Optyma™ iCO₂ 4.6kW MT

Optyma™ iCO₂ 4.6kW MTOptyma™ iCO₂ 4.6 kW (MBP) condensing unit is a robust and low-noise solution for natural refrigerant R744 compatibility.

-

if (isSmallPicture) {

Thermostatic expansion valves

Thermostatic expansion valvesThermostatic expansion valves (TXV) are available as parts programs, i.e. with separate valve body and orifice assemblies, or as complete valves (fixed orifice). The category also contains thermostatic injection valves.

Learning

- eLesson: Cold Room Module 1 - Introduction

- eLesson: Cold Room Module 2 - Applications

- eLesson: Cold Room Module 3 - Cooling Load Calculation Part 1

- eLesson: Cold Room Module 3 - Cooling Load Calculation Part 2

- eLesson: Cold Room Module 4 - Product Selection Part 1

- eLesson: Cold Room Module 4 - Product Selection Part 2

Case studies

-

if (isSmallPicture) {

Russia’s first transcritical CO₂ hypermarket

Russia’s first transcritical CO₂ hypermarketIn Voskresensk, Russian retailer Magnit has opened the first hypermarket in Russia using a transcritical booster refrigeration system with carbon dioxide (CO₂) — an eco-friendly and natural refrigerant.

-

if (isSmallPicture) {

Engineering a cool supermarket with Danfoss technology

Engineering a cool supermarket with Danfoss technologyAs part of the luxury shopping mall Paseo La Galeria, Danfoss has supplied a refrigeration control system for the supermarket “Superseis”, including systems management for better energy efficiency in the food refrigeration application.

-

if (isSmallPicture) {

Smart store brought to life at Irish service stations

Smart store brought to life at Irish service stationsWith 230 service stations around the country, Maxol Group is the leading family-owned oil company in Ireland. Beginning in 2014, Maxol stations underwent a transformation that placed increased focus on the customer experience, offering high-end snack products and convenience shopping to people on the-go. During this transformation, Maxol wanted to upgrade refrigeration, lighting and HVAC to support store ambience, ensure food safety and save on energy bills.

-

if (isSmallPicture) {

Italy's largest hypermarket opts for CO₂ refrigeration

Italy's largest hypermarket opts for CO₂ refrigerationThe use of transcritical CO₂ refrigeration in warm climates has been a hot topic for years. In Milan, the brand new 10,000 m² Iper market is a pioneer in CO₂ refrigeration using ejector technology to enhance efficiency in temperatures up to 38 °C.

-

if (isSmallPicture) {

A case study on ejector efficiency based on four test sites

A case study on ejector efficiency based on four test sitesThe F-gas regulation in Europe and similar legislation in other parts of the world push for low-GWP solutions in food retail refrigeration. CO₂ is proving to be one of the most efficient low-GWP refrigerants thanks to the unique properties of the gas combined with technological discoveries that pave the way for optimum utilization of these properties.

-

if (isSmallPicture) {

What’s your response to refrigerant legislation?

What’s your response to refrigerant legislation?All over the world, the phase-down of conventional HFCs in food retail applications has become the center of attention in the effort to combat climate change. Most recently, at the meetings of the parties under the Montreal protocol in Dubai where qualitative global phase-down of HFCs was agreed with a target of quantifying the details in 2016.

Contact us

For further information, please contact us.