Reach-in cabinet designed to receive and store fresh, frozen or pre-cooled products. Typically a stainless steel, self-contained unit used in professional kitchens, bakeries, and laboratories.

Large variety of equipment including traditional reach-ins, food prep tables, worktops, undercounters, chef bases, milk coolers, and underbar refrigerators.

Features and benefits

Superior temperature control

Lightweight and compact solutions

Stainless steel products for aggressive environments and the food & beverage industry

Reliable solutions, low operation and maintenance costs

Products suitable for use with all common refrigerants, including natural refrigerants

Long service life

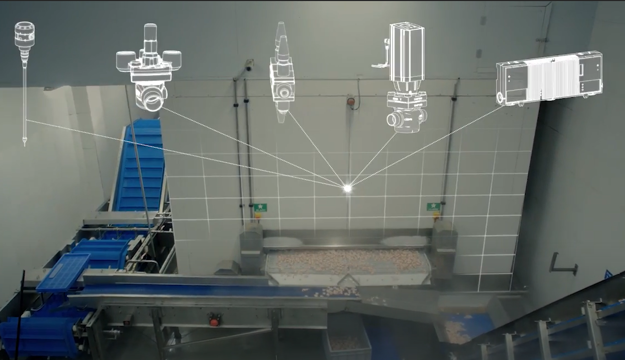

Highlights

- TU expansion valve for improved energy efficiency compared to capillary tube

- EVUL solenoid valve for effective hot gas defrost

- ERC/ETC electronic controllers to optimize system performance resulting in energy savings

- 1.5” DML filter drier for moisture & particle removal to protect systems against freeze-up and abrasive impurities

- ACB pressure switch for reliable hi/low pressure cutout and compressor protection

- MCHE Serpentine condenser coil to minimize refrigerant charge and improve efficiency

- Light commercial compressors

Related products

-

if (isSmallPicture) {

EVUL solenoid valves, normally closed

EVUL solenoid valves, normally closedEVUL solenoid valves are designed to fit into compact refrigeration systems and can be applied in liquid, suction, and hot gas lines. EVUL solenoid valves can be used in many different refrigeration systems and are specially designed for commercial refrigeration systems, refrigeration appliances, liquid coolers, ice cube machines, mobile refrigeration systems, heat pump systems and air conditioning units.

-

if (isSmallPicture) {

Hydrocarbon compressors

Hydrocarbon compressors -

if (isSmallPicture) {

Compressors for refrigeration

Compressors for refrigerationDanfoss focuses on providing energy efficient, sustainable and smart refrigeration compressors for a varied range of commercial applications such as cold rooms, display windows, ice making machines, glass door merchandizers, process cooling etc. Their qualification with lower GWP refrigerants make them compliant with refrigerant regulations such as F-Gas in Europe.

-

if (isSmallPicture) {

Filter driers

Filter driersFilter driers in hermetic design are ideal for commercial refrigeration applications requiring high drying capacity to prevent acid formation in the system.

-

if (isSmallPicture) {

ACB cartridge pressure switches

ACB cartridge pressure switchesACB cartridge pressure switch is a small disc type pressure switch for use in refrigeration and air conditioning systems. ACB is as standard equipped with a 6 amp contact system with automatic or manual reset.

Case studies

-

if (isSmallPicture) {

Upgrading Industrial Refrigeration with Danfoss PLC Controls

Upgrading Industrial Refrigeration with Danfoss PLC ControlsWhen Jack Link’s Snacks, a Wisconsin-based manufacturer of beef and turkey jerky snacks, wanted to double the size of their production facility in 2022, they knew they needed to upgrade their refrigeration system. With a larger system – 50 new evaporators, 2 air handlers, plus new condensers, compressors, a recirculator and receiver - came the need for a more robust PLC (programmable logic controller) system to help them manage and monitor temperatures and refrigerant cycle performance for a larger production and storage footprint.

-

if (isSmallPicture) {

Turning today’s farmers into tomorrow’s global suppliers

Turning today’s farmers into tomorrow’s global suppliersLearn how at Danfoss, we believe in engineering the food supply for tomorrow through precision in temperature control for the IQF and cold stores, Danfoss solutions helped sustain the food quality and improve the shelf life of the farmer’s produce. Further, Danfoss’ cold chain technology helped make the refrigeration systems at Pagro Foods versatile thus helping save energy of up to 20% which further adds to the farmer’s profitability.

-

if (isSmallPicture) {

Future-Ready Refrigeration Solutions | Danfoss

Future-Ready Refrigeration Solutions | DanfossRead to know how Danfoss provided future-ready refrigeration solutions to help Ananda Foods improve efficiency, enhance productivity, and delivering quality produce to its global clients through its efficient refrigeration systems for the food industry.

-

if (isSmallPicture) {

Danfoss ADC lab testing helps Haglund improve energy efficiency by 34%

Danfoss ADC lab testing helps Haglund improve energy efficiency by 34%Refrigeration manufacturer Haglund Industri AB wanted to achieve energy efficiency class A. Experts at the Danfoss Application Development Center (ADC) rigorously tested new component packages and reported energy savings up to 34%.

-

if (isSmallPicture) {

Hot gas defrost - the next step in commercial kitchen refrigeration

Hot gas defrost - the next step in commercial kitchen refrigerationAs authorities and customers focus on energy efficiency standards and ratings to understand not just what a commercial refrigeration unit costs to buy, but what it costs to operate, the refrigeration design engineer needs to look again at the fundamentals and consider new approaches.

-

if (isSmallPicture) {

Hot gas defrost of low temperature refrigeration evaporators with natural refrigerants

Hot gas defrost of low temperature refrigeration evaporators with natural refrigerantsIndustrial refrigeration systems predominantly use natural refrigerants, primarily ammonia and more recently CO2 Energy efficiency and the effective operation of those systems are the key parameters for operators of the plants The focus of the white paper is the comparisons of hot gas defrost strategy control methods, both on the hot gas side as well as on the condensate drain

Videos

Contact us

For further information, please contact us.