Pump optimization reduces operating costs

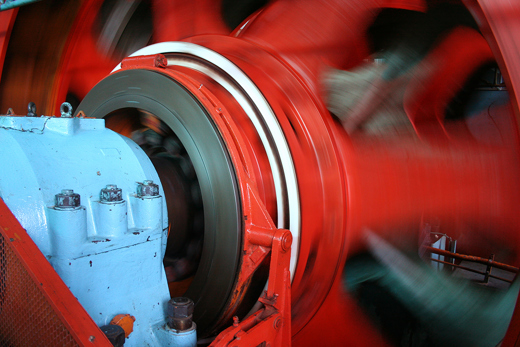

Pumps perform a myriad of tasks throughout mining operations. By investing in performance optimization with AC drives, you can achieve more efficient pumping, better equipment protection and lower operating costs in a lot of different areas.

Optimize dewatering pump skids

Many mine sites prefer to use an electric-driven pump skid instead of the traditional diesel-engine-driven pump skid, for environmental and cost reduction reasons. This is possible when there is an electrical supply close to the dewatering pump skid location.

Instead of a diesel engine, an electric-driven pump skid typically uses an AC motor and drive to set the flow rate of the dewatering pump. Normally the initial cost of an electric-driven skid is higher than the diesel-driven alternative, but the operating costs are significantly lower. The higher initial investment is recovered very quickly, often within months. As there is no need to change the oil of a diesel engine every few hundred operating hours, or pay for refueling trucks and labor, this results in even greater savings in maintenance and operating costs.

For dewatering of open pit mines with submersible pumps, Danfoss AC drives perform these important tasks and offer these advantages to optimize performance of the dewatering pump skid:

- Smaller pump diameter possible, compared to direct on line (DOL) operation

- Control of the water level of derating pumps, enabling elimination of valves

- Transfer of data to main station via radio or satellite

- Software change via satellite

- Dry run protection for the pump

- Cost of changing out pumps eliminated, since the control range is wider with drives compared to valves

- Independent operation with PID level control and sleep mode, when the desired water level is reached. When the level rises again the pump restarts without the need for an external signal

Danfoss AC drives also offer the advantage of compatibility with all typical motor technologies, such as induction motors (IM), synchronous reluctance motors (SynRM), and permanent-magnet (PM) motors. This flexibility enables you to optimize the system with the motor brands and technologies you prefer.

Solving dewatering pump skid challenges

Common challenges for drives on electric-driven pump skids include

- the limited space available. The size of the drive often impacts the size and therefore cost of the pump skid, and the drilling and creation costs of the well

- the harsh, dusty and often hot environment where the pump skid is installed

Danfoss drives address these challenges with ease and are used extensively on dewatering pump skids on many mine sites. Their compact enclosures often enable the pump skid manufacturer to minimize the size and cost of the skid. Their robust, high ambient temperature design ensures reliable, long lifetime of operation even when installed on a dewatering pump skid out in the open, on a hot, humid mine site with mining trucks kicking up dust as they pass by every few minutes.

Since IP66 enclosures are available for a wide power range, it is easy to install these drives on the pump skid, with a simple weather shield to provide shading. This solution is robust, reliable, and requires only a minimum level of maintenance.

80 kW power savings thanks to reduced substation heat load at Kolomela mine, South Africa

VLT® drives are installed on a mine dewatering system that distributes water to the plant operations as well as the local town water supply.

Get more information

Read the Mining and minerals brochure

Read more about Energy and natural resources

Products

-

if (isSmallPicture) {

VACON® 100 X

VACON® 100 XA drive for indoor and outdoor applications that withstands high pressure and vibration levels, water, heat and dirt.

-

if (isSmallPicture) {

VACON® NXP Air Cooled

VACON® NXP Air CooledDesigned for a broad range of demanding applications, focusing on higher power sizes and system drives.

Case studies

-

if (isSmallPicture) {

DrivePro® services enhance security of heat supply for 49,000 apartments in Gliwice

DrivePro® services enhance security of heat supply for 49,000 apartments in GliwicePOLAND: At district heating company PEC Gliwice, AC drives reduce energy consumption of electric motors by up to 40%. DrivePro® Site Assessment audits help ensure optimal efficiency.

-

if (isSmallPicture) {

AEL Intelligent Blasting cuts energy consumption by 500 kWh per hour

AEL Intelligent Blasting cuts energy consumption by 500 kWh per hourThis 720 Mtpd nitric acid plant in South Africa saves 3.6 M Rand annually on operating costs, thanks to to VLT® drive control of electric pumps and motors.

-

if (isSmallPicture) {

Italcementi enjoys optimized process performance in all conditions

Italcementi enjoys optimized process performance in all conditionsItalcementi chose the VLT® AutomationDrive FC 302 to ensure optimized process performance in their harsh environments.

-

if (isSmallPicture) {

80 kW power savings at Kolomela mine

80 kW power savings at Kolomela mineBack-channel cooling in VLT® AutomationDrives reduces substation heat load enabling use of a smaller air-conditioning system with lower power consumption.

-

if (isSmallPicture) {

30% energy reduction for Yamana Gold

30% energy reduction for Yamana GoldVACON® AC drives improve the operation of underground ventilation and pumping systems and cut energy consumption of many application processes.

-

if (isSmallPicture) {

Optimized production at KWB Coal Mine

Optimized production at KWB Coal Mine90 kW VLT® Drives ease the mechanical stress on the heavy equipment and improve steering when the excavator turns sideways.

Contact us

For further information please contact us