Better chillers - from the inside out

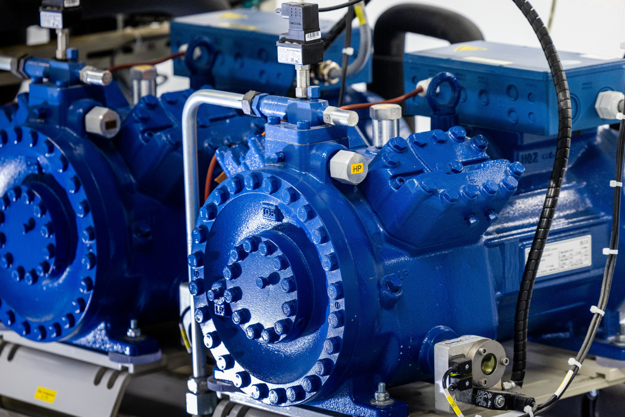

The constant innovation in chiller design is driven by new demands for energy efficiency, local regulations and standards such as LEED, combined with requirements for new, low GWP refrigerants.

Increasing population, level of comfort and high penetration of IT technologies are putting strong pressure on electric grids and driving up overall energy consumption.

The next generations of chillers and HVAC for new builds as well as retrofits are designed to meet new standards. The revolution in the A/C market opens up new opportunities. To meet the needs of an increasingly complex HVAC market, our extensive range of components offer functional benefits and savings throughout the lifecycle of the chiller system from development and operating costs to servicing and maintenance.

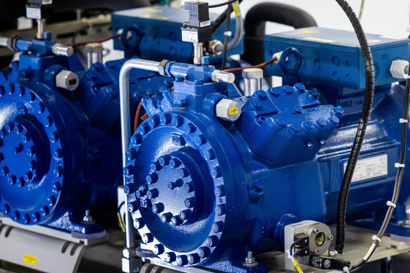

Danfoss can offer different options for meeting these requirements in air-cooled and water-cooled chillers, using scroll, centrifugal or screw technology, with excellent technical support from our expert teams. Compressors can be configured as tandems, trios or using inverter or Turbocor technology. With our electric expansion valves, controllers and sensors we can supply you with the right solutions for a highly efficient air conditioning system that responds quickly to variable operating conditions ensuring constant user comfort.

Case studies

Danfoss products and solutions make up to 70% of chiller systems and bring multiple benefits for OEMs, consulting engineers and building owners in various industries and building types. Explore the case stories here.

Features and benefits

All you need in one place, delivered by highly experienced air conditioning experts

High energy efficiency

Products optimized for environmentally friendly, low GWP refrigerants

Reduced applied costs and short payback times

Dedicated technical and customer service around the world

Eco labelling options

More chiller info?

Building water-cooled and air-cooled chillers with Danfoss products and solutions enables you to optimize energy efficiency, reduce development time and obtain reliable performance for multiple chiller platform types and uses.

Variable Speed fan and modular chillers

Is variable fan speed the answer to part-load efficiency in modular air-cooled chillers and heat pumps? Read this article based on lab tests

Downloads

Features and benefits

All you need in one place, delivered by highly experienced air conditioning experts

High energy efficiency

Products optimized for environmentally friendly, low GWP refrigerants

Reduced applied costs and short payback times

Dedicated technical and customer service around the world

Eco labelling options

Related products

-

if (isSmallPicture) {

Micro Plate™ technology

Micro Plate™ technologyThe next step in application-focused, high-performance heat exchanger

design, Micro Plates™ are a revolutionary technology, specially created for

district energy solutions and for use in heat pumps, chillers, and close control

systems for cooling capacities up 800 kW / 225 TR. -

if (isSmallPicture) {

Liquid level sensors

Liquid level sensorsThe AKS 4100 liquid level sensor takes you to a whole new level of flexibility and accuracy. With TDR guided radar technology, the sensor is fully adapted to industrial refrigeration – reliable and with high accuracy.

-

if (isSmallPicture) {

Sight glasses

Sight glassesSGP is a series of sight glasses for high pressure applications (Max Working Pressure 52 bar/754 psig). SGP is available in versions optimized for refrigerants with mineral oil e.g. HCFC, and in versions optimized for non-flammable HFC refrigerants. SGP is available with flare, solder and socket connections, and with and without moisture indicators.

-

if (isSmallPicture) {

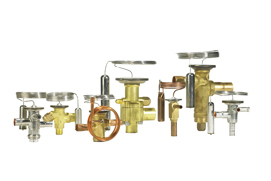

Thermostatic expansion valves

Thermostatic expansion valvesThermostatic expansion valves (TXV) are available as parts programs, i.e. with separate valve body and orifice assemblies, or as complete valves (fixed orifice). The category also contains thermostatic injection valves.

-

if (isSmallPicture) {

SVL stainless steel

SVL stainless steelThe range of stainless steel products is based on the successful modular concept from the products in the Flexline™ family, covering the SVL valves. The stainless steel products are therefore offer many of the same benefits known from the Flexline™ concept.

Learning

Chillers training program

The HVACR: Chiller training program is designed to give better understanding of Chiller applications and their related solutions. Ready to get started?

Case studies

-

if (isSmallPicture) {

Denmark's new climate-friendly hospitality giant depends on Turbocor® oil-free chiller

Denmark's new climate-friendly hospitality giant depends on Turbocor® oil-free chillerThe new Alsik hotel in Southern Denmark sets a higher standard in energy-efficiency and is built to reach 76% CO₂-neutrality. A main contributor is the 900-kW chillers by Clint (a company of G.I. Industrial Holding) which features award-winning Danfoss Turbocor oil-free compressors.

-

if (isSmallPicture) {

Oil-free compressors maintain consistent performance over time

Oil-free compressors maintain consistent performance over timeDanfoss conducted a study to see how long term operation affected performance on Danfoss Turbocor® compressors. The results showed that oil-free, magnetic bearing compressors maintained consistent performance even after 10+ years of operation.

-

if (isSmallPicture) {

Satellite launch towers

Satellite launch towersThe satellite launch tower is a vital facility. Reliable energy efficient inverter HVAC unit in this critical application was secured with Danfoss solution.

-

if (isSmallPicture) {

Shopping malls

Shopping mallsInverter technology is improving one of the world's largest home DYI stores and helping gain Brazil’s first sustainability certificate with an innovative air conditioning installation.

-

if (isSmallPicture) {

Research laboratories

Research laboratoriesRenovation of Key Laboratory in Shanghai illustrates the benefits of temperature control and energy savings in critical applications with inverter technologies

-

if (isSmallPicture) {

Process chillers

Process chillersVariable speed with Danfoss Turbocor Oil free centrifugal compressor guarantees reliable process cooling and efficient comfort cooling in factory

News

-

if (isSmallPicture) {

Danfoss is elevating industrial heat pump potentialFriday, 19 December, 2025

Danfoss is elevating industrial heat pump potentialFriday, 19 December, 2025Danfoss is addressing the increasing demand for industrial heat pumps by offering technologies capable of reaching 120°C/248°F today and 150°C/302°F on the horizon.

-

if (isSmallPicture) {

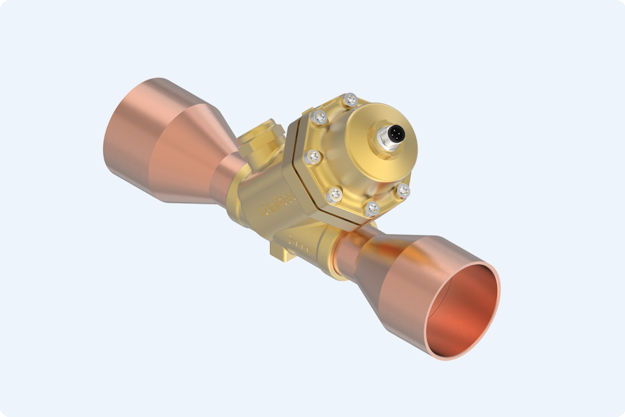

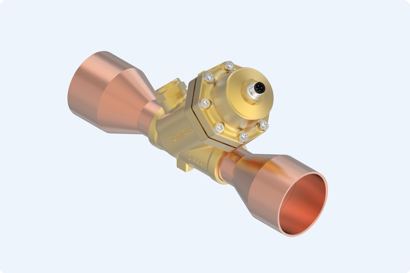

New-to-market PTS staging valves enhance reliability in centrifugal chillers and heat pumpsWednesday, 10 December, 2025

New-to-market PTS staging valves enhance reliability in centrifugal chillers and heat pumpsWednesday, 10 December, 2025PTS staging valves enhance reliability and efficiency in centrifugal chillers and heat pumps, providing fast startup, surge prevention, and stable performance for critical applications like data centers, hospitals, and industrial processes.

-

if (isSmallPicture) {

Find the right drive with Danfoss DriveFinder | VFD selection toolWednesday, 15 October, 2025

Find the right drive with Danfoss DriveFinder | VFD selection toolWednesday, 15 October, 2025Need to find the right variable frequency drive (VFD) for your application? Then try Danfoss DriveFinder. With a few simple questions, this tool helps you find the best drive for the task, as well as a trusted supplier.

Contact us

For further information, please contact us.