Enable predictive and condition-based maintenance with intelligent drives

See how you can turn the frequency drive you already have into the smartest sensor in your system. A sensor that enables predictive and condition-based maintenance capabilities, processes data on the edge, and sends data wherever it’s needed. Explore how intelligent drives solve potentially critical problems in three different applications.

Intelligent drives in your application

Maximize performance and minimize adverse application events with intelligent drives. For most applications, no extra instrumentation is required. And by only distributing relevant data, the total cost of the IoT solution is significantly lowered. Intelligent drives connect with multiple input sources, such as the Programmable Logic Controller (PLC), on-premises system, or the cloud, allowing an AC drive to accurately control speed. The drive monitors, analyzes and interprets data gathered from internal and external sensors to optimize performance and predict maintenance needs. And it sends key insights to the right destinations specified by the operator.

HVAC

Increase uptime and lifespan with early detection

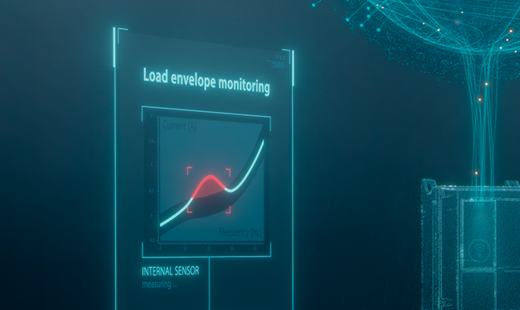

Intelligent drives sense activity beyond the drive using internal measurements. They can perform air filter monitoring either without sensors, by accurately estimating the load of the fan, or by using a drive-attached pressure transmitter. Intelligent drives have a pressure-to-flow conversion feature that limits the need for external sensors. All data can be shared with operators and any cloud or building management system for optimal performance.

Water

Maximize pump uptime with intelligent drives

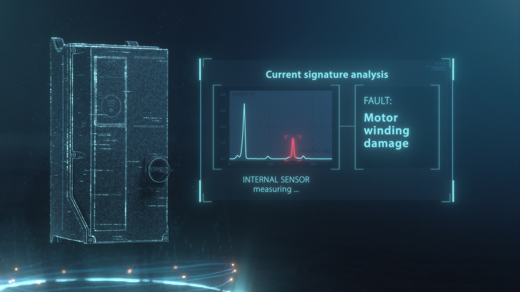

Intelligent drives have built-in smart logic control, which reduces the need for PLC capacity. The drives limit the need for extra sensors with intelligent troubleshooting that makes it easy to find and resolve faults. Their Cascade Controller can skip faulty pumps in its staging sequences. And they share insights with the cloud or on-premises system depending on the configuration.

Production lines

Trigger preventive maintenance to avoid downtime

Intelligent drives can use inputs from external sensors, such as vibration sensors. This data is correlated with internal variables, including operating speed or load. The drive performs condition monitoring of equipment in service and provides early warnings in case a degradation of performance is detected. Notification can be provided through the on-premises control system or a cloud solution.