Despite a lot of attention and measures to prevent legionella in residential and commercial buildings such as hotels and hospitals, periodically a new outbreak with sometimes fatal outcome reaches the news. According to The World Health Organization a lack of appropriate methods to diagnosing the infection or sufficient surveillance systems, the exact rate of occurrence is unknown. In Europe, Australian and the USA there are 10-15 cases detected per million population, per year.

As commonly known the root cause of people suffering from the Legionnaires' disease, a severe form of pneumonia caused by inhalation of aerosols containing legionella, is the Legionella pneumophila bacteria. These bacteria can often be found in poorly maintained artificial water systems, particularly cooling towers or evaporative condensers associated with air conditioning and industrial cooling, hot and cold water systems in public and private buildings, and whirlpool spas.

This article focuses on how to reduce the risks of legionella contamination in Domestic Hot Water (DHW) systems.

Issues and challenges in DHW systems

Knowing that the legionella bacteria grows in number when it’s in water with temperatures between 25-46 ºC, it is clear hot water systems are a possible threat for public health and require as much as possible prevention measures. These start with acknowledging the issues and challenges in these systems;

- System designs are often not documented and can easy be wrong dimensioned or have blind ends with stagnant water

- Increasing the water temperature from 45°C to (legionella safe) 60°C results in accelerated calcium sedimentation times (4x) and faster corrosion process (10x), shortening the life-time value of the system significantly

- Circulation pumps are often too big or too small

Often pipes are not insulated - 70% - 80% of DHW systems have no or poorly hydronic balance, causing zones with overheated water and other zones with underheated water

All in all, the challenges not only relate to achieving a system with reduced risk of legionella contamination. In addition, energy-efficient operation and user comfort are important aspects that require a proper solution.

Common used, inefficient solutions

To overcome some of the above-mentioned challenges in DHW systems ‘the easy way’, boiler temperatures are increased to provide a higher supply temperature and/or the circulation pump-head is increased. Such ‘work-arounds’ are neither an efficient nor a reliable solution since an increased temperature will lead to extra heat losses, wasting energy, and shorten the lifetime of the system.

Another commonly used, but inefficient, solution is to balance DHW systems with manual balancing valves as used for HVAC heating and cooling constant flow systems. These balancing valves don’t adapt to the dynamic nature of DHW systems and often don’t have the necessary certifications to be used in drinking water systems.

The safe, energy-efficient and comfort providing solution

The best compromise between system safety, energy-efficiency and user comfort in DHW systems is achieved by applying thermal balancing valves. They are set to a safe water temperature that doesn’t allow the legionella bacteria to grow, e.g. at 50°C. The valves are installed in every riser of the system, close to the circulation pipe. The valves ensure hydronic balance, safe and constant temperatures and have the system run energy-efficiently, while providing user comfort with short waiting times at the same time.

Expand with electronic disinfection

The use of thermal balancing valves will provide a safe DHW system, but some systems require a higher degree of reliability and safety. E.g. in public buildings such as hospitals and hotels there are regulations to monitor system temperatures, apply periodic water temperature increases and other measurements to have full control of the system and insights to possible legionella threads.

For such buildings it is recommended to establish an electronic controlled temperature registration, monitoring and thermal disinfection solution. Such a system reduces the risk of legionella contamination even further by periodically increasing the water temperature to a level it kills the legionella bacteria. At a temperature of 65°C it takes only 10 minutes to disinfect the water. Electronic disinfection is not only a good solution to kill the legionella. They also lower operational costs and increase the reliability of both the DHW system and required data collection.

Danfoss thermal balancing & electronic disinfection solution

Danfoss has been offering a thermal balancing and electronic disinfections solution for DHW systems for about two decades. The solution consists of two main products:

Together they provide an advanced and cost-effective solution to reduce the risk of Legionella by automatically monitoring and storing temperature data.

Both products have been significantly upgraded to perform even better. The MTCV has recently been improved by using a special POM polymer main cone and lead-free materials used for all components that are in direct contact with the water.

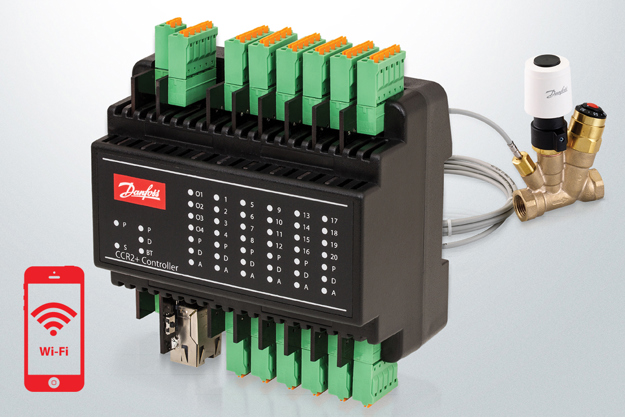

The CCR2+ is the successor of CCR2 and ads a lot of modern technologies to the electronic control process. For example, it now includes remote control and monitoring of DHW system temperatures on a mobile device connected to WiFi and has the option for full integration with Building Management Systems (BMS). All temperatures are logged into the controller, and e.g. the facility manager can access the data on his mobile phone or receive alarms and notifications automatically.

For more information: