Harmonics compliance: Use mitigation only when needed

Excessive total harmonic distortion in the distribution network costs money. You risk damage to critical equipment, reduced productivity and lower efficiency. Danfoss gives you expert advice on how to reduce this risk, at optimal cost. Using new drive technologies, you can save significantly on sizing and dimensioning of the electrical network, whilst mitigating harmonic content.. Therefore, to optimize the overall electrical system, it’s vital to select the drive (VFD) early in the system design phase.

How can you curb costs and still comply with power quality regulations?

What’ s new in variable speed drive technology?

Today, harmonic mitigation in drive systems has improved. Variable speed drive systems optimized for low-harmonic performance can now operate at 3-5% total harmonic distortion (THDi), at unity power factor, with lower common mode impact, and lower supra harmonic impact. Drives can also eliminate the full load current impacts caused by direct-online (DOL) motor starting. All of this means that supply transformers and backup generators can be dimensioned significantly (10-30%) smaller. Cables, fuses and switchgear can also be smaller. These components are expensive and can affect the ability to meet the budget constraints of a project. Careful, early drive (VFD) selection can therefore play a major part in ensuring project success.

Is harmonic distortion costing you money and downtime?

Factors impacting choice of harmonic mitigation methods include: compliance load profile, power factor distribution, electrical grid conditions, physical size of the installation (especially for retrofits), efficiency, and performance of power systems.

Harmonic mitigation: When designing a system, plan the drive (VFD) first

Using new drive technologies, you can mitigate harmonics while saving significantly on sizing and dimensioning of the electrical network. Therefore, to optimize the overall electrical system, it is vital to select the drive (VFD) early in the power system design phase. Drives offer much more than just turning your motors.

Optimize electrical system design

When designing an electrical system, optimizing for harmonic mitigation also means optimizing system design for cost, power quality, and Scope 1, 2, and 3 emissions. Whether for new-build or retrofit, design the electrical system to ensure:

- Reduced initial up front capital cost

- Minimal long-term operational costs

- Minimal practicable impact of harmonics from drives on the supply network and the wider system, including driven loads

Consider the needs for lower greenhouse gas (GHG) emissions in accordance with legislation. The design must also match the ambition of the site (or client) to meet their Scope 1,2, and 3 (GHG) emission targets, and commitments to achieve carbon net zero.

Plan a new build

Save money on large investments

For new builds, specifying the right low-harmonic drive means you can dimension generators and transformers smaller and save money on the large capital investments.

Early considerations on grid power quality allow for cost-optimized mitigations, such as combining AFE drives, active filters, passive filters and 6-pulse drives, to achieve the most cost-effective, compliant solution.

Select drives early. Danfoss can help you reduce total harmonic distortion in the best way.

The drives you select can make a big difference to the overall design. Consider the drives early in your project design by including electrical engineers in your initial planning. With good preventive measures in place, you can reduce dimensioning of the whole switchgear transmission chain for optimal CAPEX. Use the Danfoss tool MyDrive® Harmonics or contact your local office for expert advice in using harmonic calculations to dimension smaller transformers and generators.

Downsize transformers and generators by up to 30%

- To design a greenfield system, it is imperative to consider the VSD topology as early as possible.

- By considering the VSDs (and filters) early, you can downsize transformers and generators by 10-30% compared with conventional approaches. Switchgear dimensioning is also affected.

- Refine the design to obtain maximum benefits by placing centralized filters strategically, and deciding when to use AFE technology to best advantage.

Plan the drive first: Then dimension other system components

When you design systems for harmonics compliance, choosing the best drive for variable speed control will reduce total harmonic distortion (THD). By reducing THD, you can optimize the dimensioning of every other component.

Using the right ultra low-harmonic or traditional drives, you can reduce the cost of buying and running

- Supply components

- Network components

- Motors and driven loads

Follow these 3 steps

Follow these steps to select the drive and filter early, then reduce dimensioning of all other equipment for maximum benefit. Or contact Danfoss for design support.

Plan an upgrade

Choose wisely for significant OPEX savings

In an upgrade project, typically you need to maximize the impact of the retrofit without overloading the existing electrical infrastructure.

The right choices can reduce your operating costs significantly. Choose the right drives to prevent the upgrade from overloading your system. Consider aligning with a company like Danfoss, that understands the problem and can offer the full range of solutions available - because system scenarios differ, and each solution has its merits.

Follow these 3 steps

- To connect additional drives (VSDs) to existing transformers, it is imperative to know the existing load on the transformer

- Perform a harmonic survey to determine the level of distortion already present. Use the MyDrive® Harmonics tool to determine the impact of harmonics on your system, then estimate the benefits of harmonic mitigation solutions from Danfoss

- Design the system to “clean up” any existing harmonic distortion, as well as ensuring the new drive load can be added with no issues

With a wide portfolio of mitigation technology choices, you have the freedom to select the best approach. Danfoss offers support for your system design and delivers the full range of mitigation solutions.

Maximize system performance with our harmonic mitigation solutions

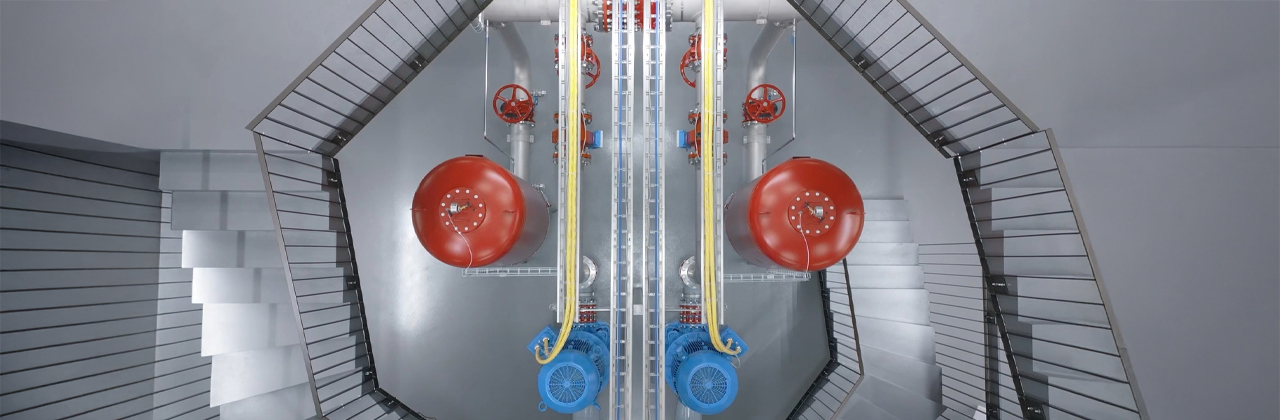

Case studies

Want to learn more about harmonic distortion?

Watch the interview and discover what our expert has to say about harmonic interference and total harmonic distortion, and how to tackle it in the most energy-efficient way possible — while optimizing your system.

Shine a light on your system performance

Use the MyDrive® Harmonics tool to calculate harmonic frequencies and interference in your system — and design a harmonic mitigation solution fit for your needs. Simply use the power circuit simulator included to perform a simulation of your system so you can pinpoint where changes need to be made. And control the harmonics generated in the most efficient way possible.

Related products

Danfoss offers a full portfolio of products for harmonic mitigation in high and low power ranges, compatible with all motor types. The range includes low harmonic drives, active frond-end drives, active and passive filters, and input and output filters. Our DrivePro® service offerings also support you in ensuring smooth operations and product longevity. DrivePro® services help to identify potential issues caused by excessive harmonic distortion, combined with recommendations for dedicated mitigation actions.

-

if (isSmallPicture) {

Danfoss Advanced Active Filter AAF 007

Danfoss Advanced Active Filter AAF 007Mitigate harmonics, correct power factor, and compensate imbalance, all in one product. Offering exceptional high efficiency, AAF 007 suits all Danfoss drives.

-

if (isSmallPicture) {

iC2-Micro

iC2-MicroThis next-generation micro drive gives you great cost effectiveness, durable reliability, and user-friendly commissioning and operation, all in a compact package.

-

if (isSmallPicture) {

VLT® HVAC Drive FC 102

VLT® HVAC Drive FC 102This tough and savvy FC102 drive enhances pump and fan applications in building management systems, and runs outdoors in most climates.

-

if (isSmallPicture) {

VLT® AQUA Drive FC 202

VLT® AQUA Drive FC 202VLT® AQUA Drive FC 202 controls all types of pumps and comes equipped with a cascade controller.

-

if (isSmallPicture) {

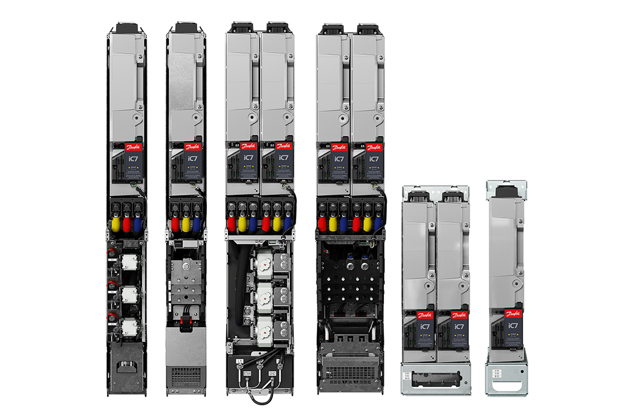

iC7-Automation

iC7-AutomationWhatever the environment, the iC7-Automation delivers the reliability and performance you need. With connectivity, security and intelligence, this drive lets you take advantage of the latest in Industrial IoT.

-

if (isSmallPicture) {

iC7 Filters

iC7 FiltersUse filters to ensure the best possible reliability and efficiency for AC drives in system configurations where power quality and motor protection is a high priority.

-

if (isSmallPicture) {

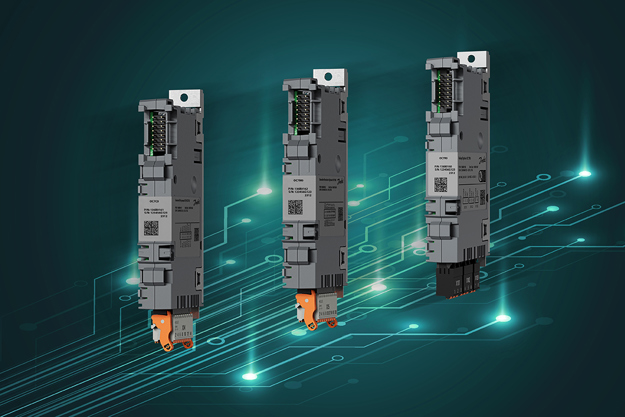

iC7 Functional extensions

iC7 Functional extensionsFunctional extensions are options which increase the flexibility of an AC drive by extending I/Os and by providing dedicated interfaces for a wide variety of feedback devices.

-

if (isSmallPicture) {

iC7-Hybrid

iC7-HybridThe iC7-Hybrid power converter is your ticket to join the energy transition. Tap into energy savings with hybrid and pure electric solutions in marine power conversions. Enhance smart grid applications such as energy storage, shore supply, charging and electrolysis.

-

if (isSmallPicture) {

iC7-Marine

iC7-MarineEnter a new dimension of opportunities with this ultra-compact drive. As well as high power density, iC7-Marine gives you a powerful combination of intelligence and shaft performance, ready for the most challenging of applications.