A building co-operative in Szczecin, Poland, has reduced the energy consumption in their one-pipe heating system by 18 percent with a solution five times cheaper than a conversion to a two-pipe system.

One-pipe heating systems can be a major challenge when it comes to indoor comfort and energy savings. An unbalanced installation will result in uneven heat distribution and unnecessary heat circulation. Residents and building owners experience this when the temperature drops and efforts to save energy by turning down thermostats are ineffective. Some radiators in the circuit are melting hot while others are freezing cold. In other words, it is often close to impossible to control the heating efficiently in one-pipe systems.

Solutions for energy savings were needed in Szczecin

A six-building co-operative in Szczecin experienced the typical problems of a one-pipe system. Initiatives to limit the heat loss had already been introduced from 1996-2002 with insulation of the walls, putting in new windows and the installation of Danfoss thermostatic radiator valves on 697 radiators in each building. It helped to a certain degree. But energy consumption remained relatively high and the residents continued to find it difficult to achieve the right temperature in their apartments. The building co-operative realised that they needed to do something about the one-pipe system. But, converting to a two-pipe system requires major reconstruction and sizable investment.

Substantial savings in energy and costs achieved

The building co-operative chose to invest 217,000 Euros in a modernization of the one-pipe system. A decision that saved them five times the costs of a reconstruction to a two-pipe system. And because of the 18 per cent saving in energy consumption, the investment is paid back in only 31 months.

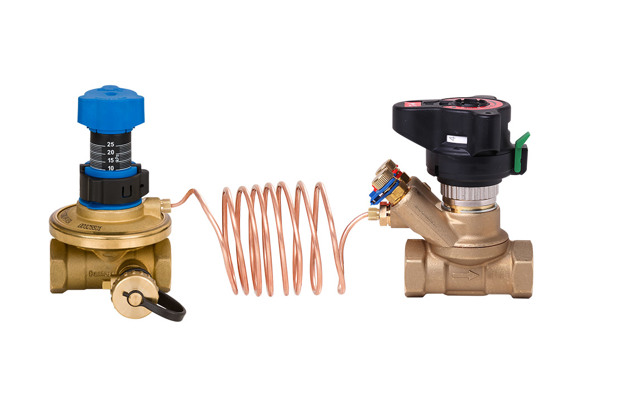

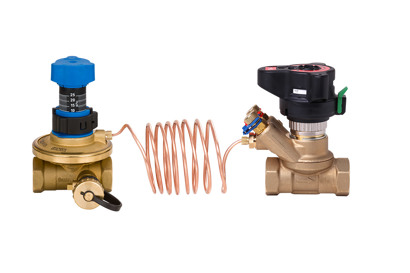

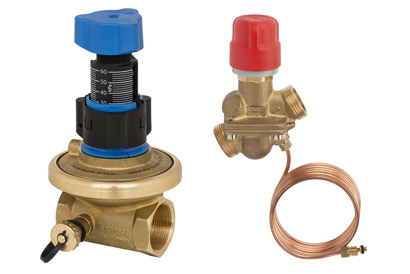

Danfoss provided a solution to control the flow of the buildings’ risers based on the return temperature of the flow. All 97 risers in each building were equipped with the Danfoss AB-QT solution, turning the one-pipe system into a variable flow system by reducing the flow rate in the riser whenever partial load conditions occur. This ensures an even heat distribution. Furthermore, it controls the flow in the risers based on the return temperature of the flow, which reduces the heat loss.

After installation the solution has been closely monitored, and the results show that the energy consumption has been reduced by 18 per cent, and CO2 emissions have been cut by 113 tons per building.

Robust installation requiring minimum maintenance

The end result is not only a cost-efficient heating solution yielding significant savings. The technical manager of the building co-operative in Szczecin is also impressed by the stability of the new solution, which has run uninterruptedly since installation. Once installed, the system does not require any additional investment apart from ordinary, occasional maintenance. In addition the number of complaints from residents has been reduced, and the 180 dwellers have expressed their satisfaction with the pleasant indoor climate and stable room temperatures no matter where the apartment is located in the buildings.

Related products

-

if (isSmallPicture) {

Automatic balancing valves

Automatic balancing valvesAutomatic balancing valves provide a dynamic balancing solution for HVAC applications. The valves eliminate pressure fluctuations occurring in variable flow systems, such as two-pipe radiator systems, at partial load conditions. These types of valves can also be used in floor heating and comfort cooling applications.

-

if (isSmallPicture) {

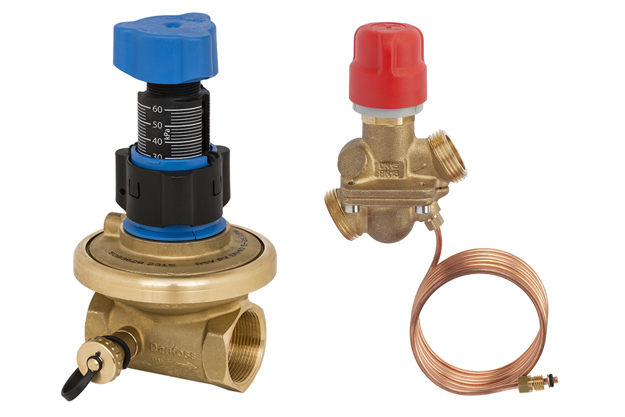

AB-PM Automatic balancing valves

AB-PM Automatic balancing valvesAB-PM is a combined balancing valve providing both differential pressure control and flow limitation. The valves eliminate pressure fluctuations at full load and partial load conditions and can be equipped with an actuator to allow zone control.