A field test performed in a residential building from 1958 shows that the installation of Danfoss Dynamic Valve™ leads to improved hydronic balancing, substantial energy savings and improved comfort for all of its residents.

Automatic balancing satisfies residents

The apartment building is a typical example for many other buildings where noise and energy efficiency complaints about the heating system occur. Automatic hydronic balancing proofs to be a simple and effective solution.

For the field test, 36 apartments and six semi-detached homes were equipped with the new dynamic valves. By replacing the old, manual or thermostatic valves with the new dynamic valves, an even flow of heat to all flats in the building was established and the thermal comfort of residents was greatly improved. Previous user complaints about room temperatures being too high or too low due to an improperly balanced heating system have consequently been eliminated, and the building owner is satisfied with the new solution.

“The new valves have improved the comfort for residents. This means that the right amount of heating is always available when the residents need it and it is easy to adjust the temperature in each room. The new valves are convenient for our janitors, too. They do not have to spend time solving problems with the heating system any more”, says Lars Johnsen, Manager, Energy Efficiency at Bovia Housing Association, renting out more than 5,000 flats.

As part of the field test, 87 manual and 88 thermostatic radiator valves were replaced by 175 new, dynamic valves and new sensors. All dynamic Automatic balancing satisfies residents valves were pre-set to match the water flow to the heat requirements of the individual rooms. The installation of Danfoss Dynamic Valve™ has led to substantial energy savings, and the pay-back time of the installation has been calculated to eight years.

Easy installation

The new dynamic valves are suited for residential buildings with traditional two-pipe heating systems. According to the installer involved in the field test, the installation of the dynamic valves was quick and easy.

“The new valve is a great achievement. We have been waiting for a valve like this for a long time. The new valve automatically adjusts the flow of water to each radiator according to temperature levels and system loads. During the installation of the 175 dynamic valves it was evident that the new valve is just as easy to install as any other valve, so all in all the dynamic valve is good news”, says Lars Petrowski, director and owner of Petrowski Plumbers who made the field test installation. With the new Danfoss Dynamic Valve™ installed on all radiators, no other balancing valves are needed in the system. The field test shows that the new installation increases the ΔT by approx. 5°C complying with the requirements of the district heating supplier.

“We are happy that we got the chance to be part of the test installation with the new valves. We are now considering similar energy renovation projects in some of the other buildings in our portfolio to save energy and to improve comfort”, says Lars Johnsen from Bovia.

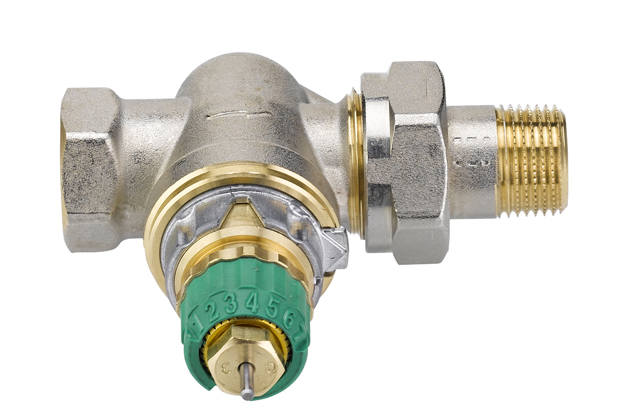

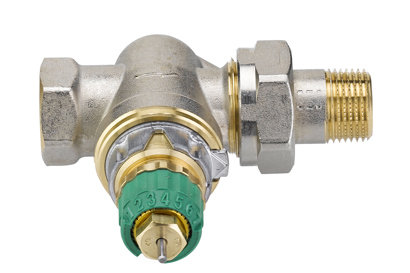

Facts about Danfoss Dynamic Valve™

Danfoss Dynamic Valve™ is a new, two-in-one radiator valve that combines temperature control with automatic hydronic balancing. Each valve has a built-in differential pressure controller that prevents pressure fluctuations, the main cause of typical heating system complaints such as noise and uneven heating. The new valve has a built-in pre-setting for maximum flow to provide each radiator with the exact, right amount of water. Once all valves in a system have been mounted and pre-set, the system is commissioned and optimized for the rest of its lifetime. No further commissioning is needed.

Related products

-

if (isSmallPicture) {

Danfoss Dynamic valve™

Danfoss Dynamic valve™Danfoss Dynamic valve™, the innovative 2-in-1 pressure independent radiator valve that ensures both optimal temperature control as well as creating automatic hydronic balance in two-pipe heating systems – all in a single valve.