POLAND: For more than a decade, Danfoss drives have helped to control the ventilation and water pressurization and distribution systems at Okocim Brewery in Brzesko. In both systems they reduce energy consumption by up to 50%. These systems also save water and reduce carbon dioxide emissions.

For many years, Carlsberg Group has focused on sustainable development, to reduce carbon dioxide emissions and decrease water and energy consumption. Therefore as a step in the process, in 2012 Okocim Brewery implemented an upgrade of of the hydrophore and ventilation systems project at its Brzesko plant. Danfoss partner Control-Service performed the upgrade using variable speed control with Danfoss VLT® drives.

The challenge: Stable water pressure and adequate air exchange

For the hydrophore system, the main challenge was to distribute water reliably throughout the brewery. The plant requires stable pressure which can adapt to the current conditions, with no hydraulic surges. Before the upgrade, the brewery experienced erratic pump shutdowns and startups, and pressure often exceeded demand.

In the ventilation system upgrade, the brewery needed to ensure adequate air exchange in the premises. Carbon dioxide removal and dew point control were also important requirements. They also wanted to collect historical data to generate advanced reports. Analysis of these data helps to develop optimal conditions for production and storage of beer.

Carlsberg was also keen to improve on maintenance and efficient support services, to ensure reliable brewery production operations.

The solution: Dedicated fan and pump control with built-in protection

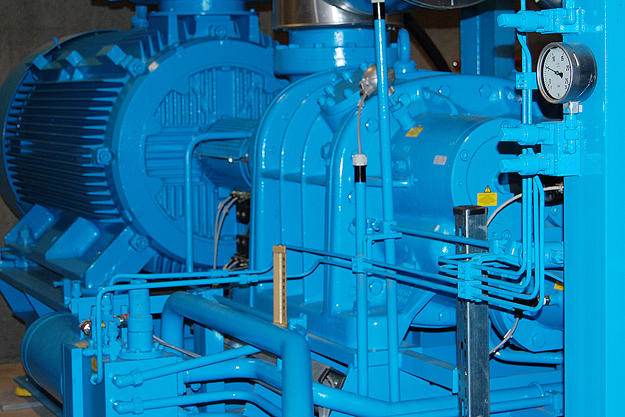

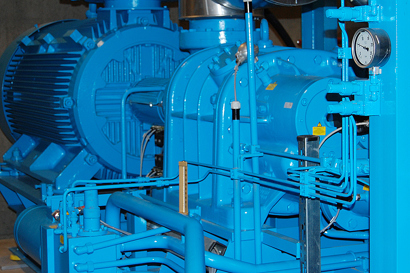

To optimize water distribution, the partner company Control-Service proposed a solution using Danfoss drives.

They used 2 x 55 kW VLT® AQUA Drive FC 202 devices, 3 x 55 kW pumps and a 55 kW soft starter. In this design, the drives do not need to switch between pumps, and the entire system is protected on several levels. If the first drive fails, another drive automatically takes over. A pressure switch also helps to maintain the preset pressure, when required.

For the ventilation system optimization, Control-Service installed VLT® HVAC Drive FC 102 with dedicated features optimized for HVAC installations. These features include smart air handling unit control with different modes of operation. A Smart Logic Controller integrated into the drive takes over PLC tasks to control the operation of valves, fans, and dampers.

Since commissioning, Control-Service has conducted ongoing proactive maintenance, including preventive maintenance of drives and soft starters. They align maintenance inspection dates with the plant production schedules, making it easier to maintain production uptime.

The outcome: 50% lower electricity bill

With the help of AC drives, the water supply, air conditioning, and ventilation systems consume approximately 50% less electricity than comparable standard solutions.

Not only did the new water distribution system meet the requirements, but the investment was also repaid within only 7 months. The dual-pump solution is approximately 17% more energy-efficient than a comparable system using only a single pump running at 100% capacity.

VLT® HVAC Drive FC 102 drives used in the HVAC system control fan operation. Air recirculation adapts to the operation cycle of the brewery. During weekends and holidays, when demand is lower, the energy consumption is reduced by up to 80%. With these exceptional results, other Carlsberg divisions have been inspired to deploy similar solutions using VLT® AQUA Drive FC 202 and VLT® HVAC Drive FC 102.

Discover the products

More case stories

-

if (isSmallPicture) {

Carlsberg brewery drives down energy consumption by 50%

Carlsberg brewery drives down energy consumption by 50%POLAND: For more than a decade, Danfoss drives have halved the power consumption at Carlsberg’s Okocim Brewery. The brewery uses less water and has lowered its emissions too.

-

if (isSmallPicture) {

Marselisborg: A path to an energy neutral water sector

Marselisborg: A path to an energy neutral water sectorMarselisborg Wastewater Treatment Plant went from energy consumer to energy producer by using VLT® AQUA Drive FC 202 from Danfoss. Learn more about that here.

-

if (isSmallPicture) {

Full-scale biogas plant in Kalundborg ensures the return of all nutrients back to nature

Full-scale biogas plant in Kalundborg ensures the return of all nutrients back to natureAC drives from Danfoss help convert biomass from insulin and enzyme production to energy.

-

if (isSmallPicture) {

Sarlux refinery saves energy with 12000 m3/day industrial desalination plant

Sarlux refinery saves energy with 12000 m3/day industrial desalination plantDanfoss solutions enabled Acciona to create an innovative sea water reverse osmosis (SWRO) modular desalination plant for the Sarlux refinery in Sardinia, reducing energy consumption compared to traditional solutions.

-

if (isSmallPicture) {

A cost-effective solution: district cooling in central Copenhagen

A cost-effective solution: district cooling in central CopenhagenEnergy efficiency was a major consideration in the design of Copenhagen’s district cooling project, where VLT® drives contribute to reducing CO2 emissions by more than 3000 t annually.

-

if (isSmallPicture) {

Cool tech for ice hockey ensures perfect match conditions

Cool tech for ice hockey ensures perfect match conditionsWhen talking about ice hockey arenas, whether you are a player or a spectator, you’re always on the winning team with Danfoss.