For decades, the centrifugal (CF) pump has been considered the best choice of high-pressure pump in large SWRO trains.

In recent years, however, the increasing focus on energy savings and reduction of CO2 emissions has led to the introduction of Isobaric Energy Recovery Devices (ERD) that typically save up to 60% of the energy. And now, large-flow and high-efficient Positive Displacement (PD) pumps designed specifically for SWRO are entering the marked with potential to bring down the power consumption by up to additional 20% or even more.

Despite the obvious advantages of using the high-efficient PD pumps, some system builders still hesitate to use them for several reasons. In some cases because the sizing of the PD pump is considered to be different from the CF pump, or because the flow control is different and requires a slightly different design of the hydraulic components around the pumps.

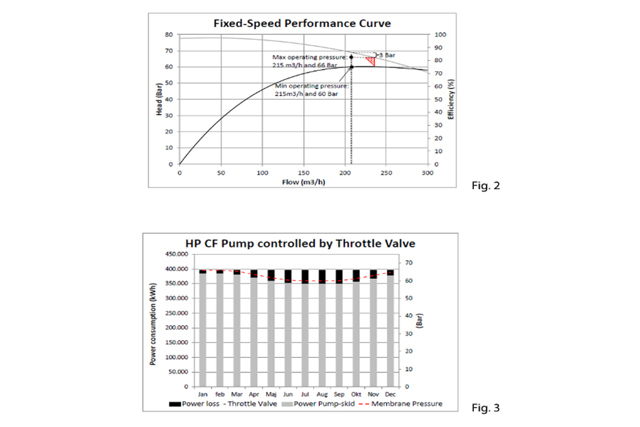

Based on an experimental set-up where the SWRO train is exposed to seasonal pressure variations, this paper will explain the difference in sizing CF pumps and PD pumps. The paper will also reveal how different set-ups in flow regulation have significant impact on energy savings when using CF pumps and PD pumps in large SWRO plants.