Cooling large buildings typically require the use of air or water-cooled chillers that produce chilled water, which then cools the air. About 39 percent of buildings over 100,000 square feet use chilled-water systems employing various compressor designs. Selecting the right chiller and compressor requires a specifying engineer to determine the building’s cooling load and the proper chiller capacity. Calculations are also done to determine the return on investment between different systems by comparing the energy cost per ton of refrigeration along with the operational costs.

When buying a new chiller, specifying engineers and facility owners naturally focus on efficiency ratings to estimate the chiller’s annual energy costs. However, there is another variable worth considering: How will the chiller and the chiller’s compressors maintain their rated performance in real-world operating conditions years after the purchase has been made? A significant factor that affects chiller performance over time is the oil used by the chiller’s compressor. Oil is used to form a seal that prevents refrigerant from returning to the suction port as well as lubricate the compressor bearings, gears, and shaft seals. While necessary for operation, the oil over time becomes entrained in the refrigerant and circulates throughout the system. Eventually, the oil coats the heat exchanger tubes, which creates a thermal barrier that degrades efficiency—a problem is known as “oil fouling.”

A number of independent third-party studies detail the consequences of oil fouling, which include:

- A drop in heat transfer ratio from 1.0 to 0.65 at oil concentrations as low as 10 percent.2

- A loss of 10 percent efficiency after five years, 20 percent efficiency loss after 10 years in oil-lubricated chillers at Tsinghua University, China.3

- As much as 30 percent performance degradation in other cases.4

Performance degradation over time is not only due to oil fouling. Another study shows that traditional oiled compressors, specifically screw compressors, suffer significant performance degradation due to excessive bearing wear, capacity slide damage, and other factors over years of operation.5 This study concluded that the screw compressor wears significantly impacts performance by the fifth year of operation, and subsequent performance degradation was found to be as high as 26 percent on average after 15 years of operation.

Download the case study as PDF to read more

Related products

-

if (isSmallPicture) {

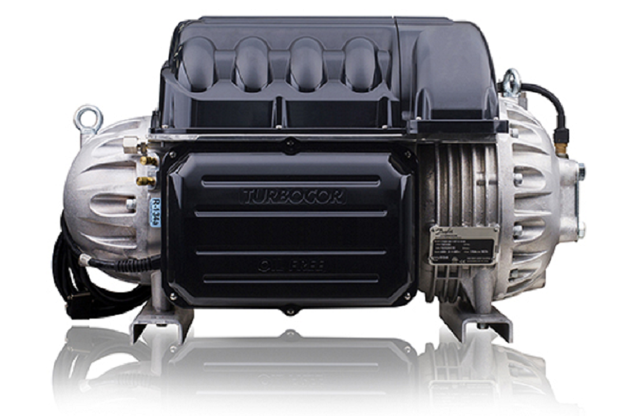

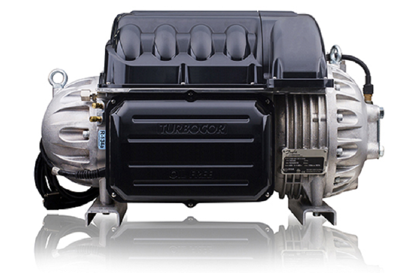

Turbocor® - TTS

Turbocor® - TTSDanfoss Turbocor®model TTS oil free compressors are available in four different models ranging from 60 tons to 200 tons / 200 to 700 kW utilizing R134a or low GWP R513A.