In the modern world of refrigeration systems, increasingly greater emphasis is placed on energy efficiency and sustainability. Electronic control systems are often the center of focus here, but it should not be forgotten that the dimensioning of refrigeration components can also make an important contribution to reducing operating costs in refrigeration systems. This is based equally on reducing pressure drops and preventing system malfunctions. The subject of this edition is the correct dimensioning of solenoid valves for refrigerant as the medium.

Function

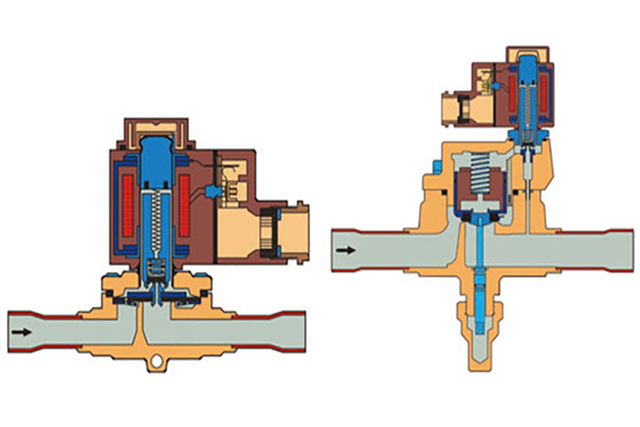

To be able to dimension a solenoid valve correctly and to know what to keep an eye on as you do so, we will now first of all take a look at the set-up of these refrigeration components. Generally speaking a solenoid valve consists of a coil and a valve housing. The coil is mounted on an armature tube. With smaller, directly-controlled valves, the movable armature opens and closes the valve by directly releasing or closing the valve seat. To achieve a better internal seal, that part of the armature that contacts with the valve seat must be given a Teflon seal disk. With servo-controlled solenoid valves the armature movement happens the same way, but in this case a servo bore hole is opened or closed, instead of the entire valve seat. In the case of servo valves with a diaphragm, this results in a movement of the diaphragm over the differential pressures on the valve, which then corresponds with the valve's opening and closing process. The principle is the same with servo solenoid valves with pistons and without a diaphragm. The valve is also opened and closed via the servo bore hole here - but using the piston mechanism, and not with a diaphragm. A rough classification according to capacity values is easily possible. The solenoid valves with the smallest capacity values are therefore mostly directly controlled. With bigger systems, there are also valves that are all fitted with diaphragms and servo-controlled. Ultimately with high capacities you will find servo-controlled piston valves. If these values are no also longer sufficient, then main valves can easily be turned into solenoid valves by means of a solenoid valve attachment. These combinations then leave practically no requirements unfulfilled with regard to the size of the system. If you open a solenoid valve and find neither a diaphragm nor a piston in it, then it will generally be a directly controlled valve. This will then have smaller connections, such as 6, 8 or 10 mm.