Danfoss AB-PM combined automatic balancing valves ensures a reliable HVAC system with low total cost of ownership. The valve secures perfect balance at all loads by guaranteeing stable flow and differential pressure for each zone. At the same time an actuator can be added to allow individual control of each zone. This provides an exceptional solution in two main applications:

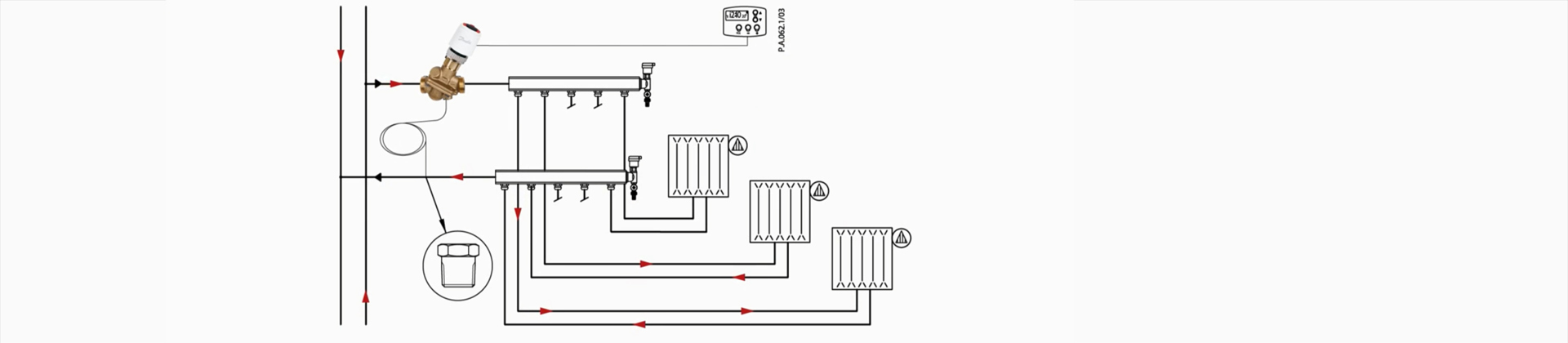

- Residential buildings (Multi Family Housing) with two-pipe heating systems with distribution systems in front of each flat, such as manifolds for hydronic floor heating

- Commercial buildings (Shell & Core) where the HVAC systems are established in stages or by different parties.

In case of residential applications, the AB-PM is mostly used in sizes DN10-32, ensuring hydronic balance for each flat e.g. in front of manifold for floor heating installations. The optional connection to a room temperature controller allow feature for each flat such as night setback or holiday mode.

In case of commercial HVAC applications, the AB-PM is mostly used in sizes DN 40-100. The automatic balancing valve can be used in shell & core buildings such as shopping malls or offices, ensuring a reliable heating system for the building owner and tenants. AB-PM is the ideal solution for such type of buildings as staged installation, handover and commissioning often occur. In such cases, the 1st stage is installation of backbone piping without terminal units (responsible building owner). The 2nd stage is the installation of terminal units in each zone (responsible tenant).

The AB-PM ensure the required flow for each zone and maintains the hydronic balance in the system in all conditions and for individual zones either with one or more terminal units.

Features and benefits

Many features in one compact valve

Combined balancing valve for differential pressure control, flow limitation and zone control

Guarantees flow and Δp for each zone

Easy, fast and simple design process

Fast installation and easy setting

AB-PM animated instructions for small DN sizes

Watch animated instructions to see how to install AB-PM

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| Brochure | AB-PM - HVAC control for shell and core and base buildings | English | Multiple | 13 Mar, 2018 | 629.4 KB | |

| Data sheet | AB-PM (DN 10-32) | English | Multiple | 14 Jul, 2022 | 1.8 MB | |

| Data sheet | AB-PM (DN 40-100) | English | Multiple | 07 Mar, 2018 | 1.8 MB | |

| Brochure | AB-PM brochure | English | Multiple | 03 Sept, 2014 | 817.4 KB | |

| Data sheet | AB-PM Rack set DN 15-20, PN10 | English | Multiple | 30 Jul, 2017 | 1.2 MB | |

| Brochure | Hydronic Balancing & Control product overview | English | Multiple | 11 Dec, 2016 | 1.1 MB | |

| Brochure | Hydronic Balancing & Control product overview | English | United Kingdom | 10 Nov, 2014 | 7.1 MB |

Drawings

Software

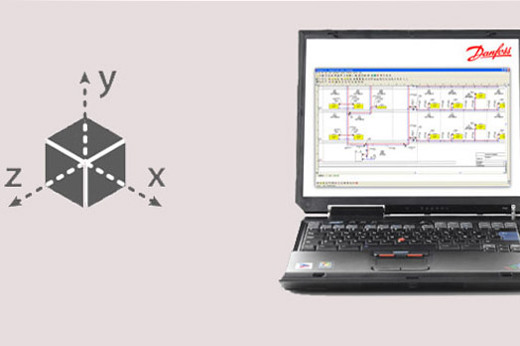

Danfoss C.H. software

Our advanced Danfoss C.H. software will help you to design and calculate the perfect heating or cooling installation with Danfoss products.

Related products

-

if (isSmallPicture) {

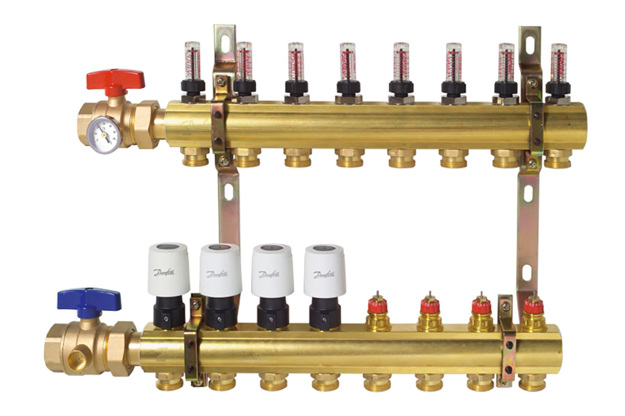

Manifolds and actuators

Manifolds and actuatorsDanfoss floor heating manifolds are characterized by their flexibility to establish the best suited manifold solution based on requirements. Select from all the components to construct a manifold with or without pre-setting, flow-meters, shut-off valves and air-vents that best fits your project.

-

if (isSmallPicture) {

GreenCon on/off room thermostats

GreenCon on/off room thermostatsGreenCon on/off room thermostats are used for room temperature control in fan coil units cooling and heating systems. By controlling room temperature in accordance with the temperature desired by user, GreenCon provides high energy efficiency while upholding and ensure optimal thermal comfort in the room.

Tender texts

Need design support?

We offer expert hydronic HVAC design and consultancy services at Danfoss' Design Support Center.