Rotary position sensors with and without shaft for mobile hydraulic applications

Danfoss DST X510 and DST X520 rotary position sensors are designed for use in mobile hydraulic applications, such as agricultural, construction, and material-handling machines.

Danfoss DST X510 and DST X520 series uses contactless Hall technology with measurement ranges up to 360°.

All sensors are designed for off-highway applications and resistant to shock and vibrations and with high electromagnetic compatibility, and come with both Ratiometric, CANopen and SAE J1939 output.

Single and redundant sensor types are available, making the complete portfolio suitable for safety-critical applications.

DST X510 sensors comes with shaft and DST X520 sensors comes without shaft, and are E1 approved.

Features and benefits

Contactless Hall technology for almost infinite sensor life time

Electrical connections: DEUTSCH 6P DT04-6P

Single or Redundant ranges up to 360° (±180°)

Output: Ratiometric, CANopen and SAE J1939

Linearity: < ± 0.5% FS

Resolution and speed of rotation:

- 12 bit (analog)

- 14 bit (CANopen/SAE J1939)

- 120 rpm max.

IP protection level IP67 – IP69K with female mating connector

Operating temperature from -40 °C to 85°C

Vibrations: 20g - 10 Hz … 2000 Hz

Conformity

CE

RoHS

E1

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| Operating guide | DST X510 and DST X520 Rotary position sensors SAE J1939 | English | Multiple | 06 Dec, 2019 | 2.5 MB | |

| Operating guide | DST X510 and DST X520 Rotary Sensor CANopen | English | Multiple | 06 Dec, 2019 | 898.9 KB | |

| Operating guide | DST X710 Entry level inclination sensor CANopen Operating guide | English | Multiple | 01 May, 2019 | 1.1 MB | |

| Operating guide | DST X720 Mid level inclination sensor | English | Multiple | 01 May, 2019 | 1.1 MB | |

| Operating guide | DST X730 Top level inclination sensor | English | Multiple | 01 May, 2019 | 983.1 KB | |

| Data sheet | Inclination position sensor, type DST X710 | English | Multiple | 26 Feb, 2021 | 2.7 MB | |

| Data sheet | Inclination position sensor, type DST X720 | English | Multiple | 03 Mar, 2021 | 11.6 MB | |

| Data sheet | Inclination position sensor, type DST X730 | English | Multiple | 03 Mar, 2021 | 4.4 MB | |

| Operating guide | Operating guide DST X800 wire position sensor | English | Multiple | 01 May, 2019 | 491.8 KB | |

| Data sheet | Rotary position sensor, type DST X510 | English | Multiple | 26 Feb, 2021 | 1.9 MB | |

| Data sheet | Rotary position sensor, type DST X520 | English | Multiple | 26 Feb, 2021 | 1.3 MB | |

| Data sheet | Wire position sensor, type DST X800 | English | Multiple | 26 Feb, 2021 | 4.4 MB |

Product range

-

if (isSmallPicture) {

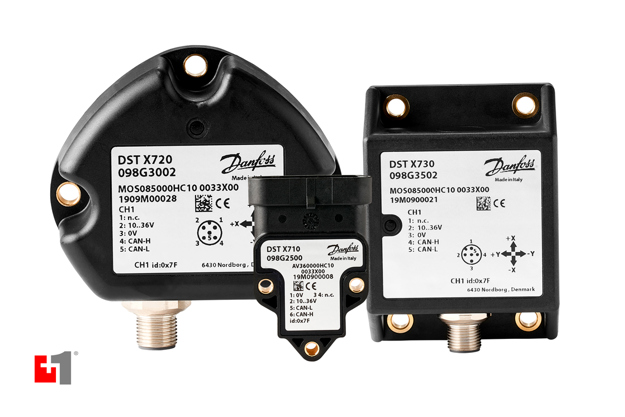

DST X710, X720 and X730 series, inclination sensors

DST X710, X720 and X730 series, inclination sensorsDanfoss program of inclinometer sensors are developed to ensure a robust and high-performance solution for applications such as agricultural- and construction machines, as well as material handling equipment. These sensors are typically used in safety applications in order to keep the inclination of a machine, or just a part of it, a safety zone for working people, under control.

-

if (isSmallPicture) {

DST X800 series, wire position sensors

DST X800 series, wire position sensorsDanfoss DST X800 wire position sensor is developed to ensure a robust and high-performance solution for applications. The stability control of e.g. a crane, telehandler or aerial platform is kept under control with draw wire sensors that determine the withdrawal of lateral stabilizers at different positions; on same applications the draw wire on the boom.

-

if (isSmallPicture) {

DST X510 and X520 series, rotary position sensors

DST X510 and X520 series, rotary position sensorsThese sensors are able to detect angles from ±15° up to 360° e.g. pedal accelerator, front or rear steering, suspension position, or cabin rotation.

Related applications

-

if (isSmallPicture) {

Agriculture

AgricultureFarmers need agricultural machines that deliver the same high productivity every season. Hydraulic solutions from Danfoss ensure world-class performance from each machine—and a comfortable, stress-free working environment for their operators.

-

if (isSmallPicture) {

Drives for cranes in mining and mineral processing

Drives for cranes in mining and mineral processingTo optimize crane and hoist performance, Danfoss offers flexible control strategies combined with energy efficiency, operating within stringent safety requirements.