Drinking water production

Whether surface water or groundwater is used for water production, Danfoss AC drives can help optimize the process and reduce energy and maintenance costs. A typical application is the control of deep well pumps, where the integrated advanced minimum speed monitor secures sufficient lubrication to protect the pump. Energy savings are achieved by selecting wells based on water level height. The VLT® AQUA Drive is also widely used in the desalination industry for controlling inlet and high-pressure pumps as well as booster pumps in relation to energy recovery.

Drinking water distribution

Within the water supply, drinking water distribution is typically the largest energy consumer. At the same time, 25–50% leakage is not unusual. By dividing the water distribution into pressure zones, the average pressure can often be reduced by 30–40%. The VLT® AQUA Drive is very widely used in boosting pumping stations to regulate pressure in each pressure zone. Integrated application software functions, such as Sleep mode, Dry run detection, Automatic Energy Optimization (AEO), Cascade control, Automatic flow compensation and Ramp functions help simplify the installation and make it more reliable, reduce the risk of water hammer, control pressure and reduce energy consumption.

Irrigation

With access to water resources becoming scarce in some regions of the world, efficient and sustainable irrigation is becoming more and more important. It’s all about supplying enough water to get maximum crop yield without using more water and energy than absolutely necessary. Danfoss AC drives adapt pressure or flow rate to the actual need. And integrated application software functions help to both protect the pipe system by limiting pressure boost and cut energy consumption.

The ultimate solution, and a very fast-growing trend, to reduce energy consumption is to use solar-powered pumps. Danfoss Drives has developed a dedicated inverter series exactly for this purpose. The VACON® product range includes a specially designed encapsulation for this environment and advanced software, meaning that operation is possible even when clouds are partially blocking sunlight from reaching the photovoltaic panels.

Wastewater canalization system

Energy optimization and SCADA control of the wastewater canalization system is also a fast-moving trend. By using the VLT® AQUA Drive’s integrated deragging function, it is possible to improve pump efficiency by 15–30% and also drastically reduce maintenance costs. The deragging function prevents pump efficiency from dropping by increasing clocking and extends pump maintenance intervals. Using an AC drive together with a SCADA system also offers the possibility to secure maximum utilization of the volume capacity in the canalization system in relation to storm water overflow.

Reduced leakage and energy consumption go hand in hand

The energy used in the water distribution system typically represents 60–80% of the total energy consumption for the whole water supply system. By adapting the pressure to the real need using pressure zones and boosting pumping stations, you can achieve energy savings of 25–40%. At the same time, you can reduce water leakage by 30–40%.

Regulating the pressure in the network can also provide the following benefits:

- a 40–55 % reduction in the amount of new pipe breaks

- a reduction in maintenance costs and expensive pipe and road repair

- limited risk of bacteria and contamination of tap water (infiltration)

- extended service life of the network

- postponed investment in plant upgrades

- reduced risk of water hammer

The Jurex seed company saves 35% on irrigation pump energy consumption

The Romanian seed company Jurex srl installs VLT® AQUA Drive frequency converters in its new irrigation pumping station.

Contact us

For further information please contact us

Case studies

-

if (isSmallPicture) {

Carlsberg brewery drives down energy consumption by 50%

Carlsberg brewery drives down energy consumption by 50%POLAND: For more than a decade, Danfoss drives have halved the power consumption at Carlsberg’s Okocim Brewery. The brewery uses less water and has lowered its emissions too.

-

if (isSmallPicture) {

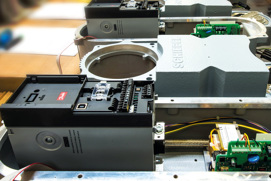

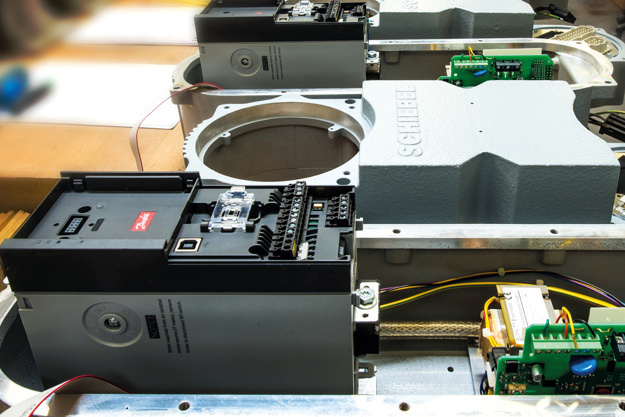

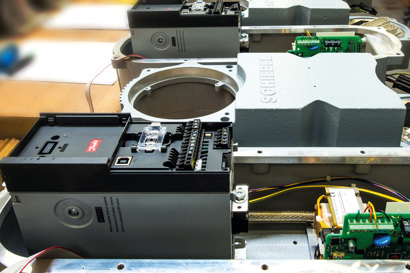

VLT® Midi Drive for precise actuator control

VLT® Midi Drive for precise actuator controlWith its compact and temperature-resistant design, the drive integrates easily into actuators from Schiebel Antriebstechnik GmbH, providing high-precision flow control.

-

if (isSmallPicture) {

Affinity Water saves £0.3 million by using Danfoss Drives

Affinity Water saves £0.3 million by using Danfoss DrivesVLT® AQUA drives recently installed at the Chertsey Water Treatment works of Affinity Water deliver savings of more than a third of a million pounds in running costs.

-

if (isSmallPicture) {

Ferrari racetrack hydro system performs exceptionally

Ferrari racetrack hydro system performs exceptionallyVLT® AQUA Drive FC 202 with IP66 protection provides fast and accurate control of pump pressure for essential aquaplaning tests.

-

if (isSmallPicture) {

Cool savings for pool pumps

Cool savings for pool pumpsBy controlling the motor in a pool, VACON® 20 Cold Plate can achieve energy savings of up to 70%.

-

if (isSmallPicture) {

Improved water pumping in Kristinestad

Improved water pumping in KristinestadVACON® 100 FLOW provides even flow and reduces pressure spikes in the water supply in the west coast of Finland.

Products

-

if (isSmallPicture) {

VACON® 100 FLOW

VACON® 100 FLOWDedicated functionality that improves flow control and saves energy in industrial pump and fan applications.

-

if (isSmallPicture) {

VLT® AQUA Drive FC 202

VLT® AQUA Drive FC 202VLT® AQUA Drive FC 202 controls all types of pumps and comes equipped with a cascade controller.

-

if (isSmallPicture) {

VACON® NXC

VACON® NXCAn enclosed drive designed for demanding applications that includes options for Active Front Ends and low harmonic solutions.