Enhance performance, reduce energy and costs

The use of AC drives in the water industry is constantly increasing. Today, drives are widely used all over the industry from water production and distribution to wastewater pumping in sewage canalization systems and wastewater treatment plants both within municipalities and the industrial side of the business. AC drives control the speed of motors in a wide range of pump, blower, mixer and dewatering applications to help enhance performance and value while saving energy and costs.

Water management doesn’t have to be highly energy consuming

Typically, water and wastewater treatment processes account for 25–40% of a municipality’s electricity bill and are the equivalent of 4% of global electricity consumption. Water and wastewater facilities are therefore normally the single-largest electricity consumer for a municipality.

With extensive use of AC drives, energy-efficient components and real-life online process control combined with energy production based on the methane from a wastewater plant’s digester, the first full-scale facilities are now in operation on a completely energy-neutral basis. This is obtained without adding external carbon. The energy neutrality covers the whole water cycle, from water production and distribution to wastewater pumping and treatment.

Wastewater treatment plants

The latest buzzwords in wastewater treatment plants are ‘Bio refinery’ and ‘Water Resource Recovery Facilities’. These cover the general acceptance that wastewater has to be considered as a resource from which both energy and valuable resources can be gained. In some of the most advanced cases, energy production has now (even without adding external carbon resources) got to a level where the energy recovered from wastewater treatment process not only covers the plant’s own needs, but also the energy needs for drinking water production and distribution as well as wastewater pumping. In other words, the whole water cycle can be considered energy neutral.

A precondition for energy neutrality is a control handle in the form of an AC drive available for all rotating equipment, so that the fully computer-controlled facility can adapt to the changing load. Typically, 30–60% of energy is used in the biological process; AC-drive control can usually cut energy consumption by 20–40%. Sludge age control by control of the RAS pumps is similarly important to both limit energy consumption and also avoid ‘burning’ carbon, which is needed in the digester for generating gas for energy production. The VLT® AQUA Drive has been chosen for some of these most advanced facilities, where high installed efficiency of the drive and greater reliability and ease of operation have been key selection criteria.

Efficient wastewater treatment and surplus energy production

In wastewater treatment plants, the high energy consumption is related to the energy-intensive processes and the continuous operation cycle: 24/7, 365 days a year. Focus in the industry has been on developing new processes and control strategies to reduce energy consumed per liter of water processed. However, the demands for improved wastewater treatment quality, for example, based on demand for enhanced nutrient removal, increase net energy consumption. This creates an even greater need to cut energy consumption based on advanced process control.

Blowers or surface aerators typically consume 40–60 % of the total energy used in wastewater treatment plants. Controlling the aeration equipment with Danfoss AC drives can deliver energy savings of 30–50%.

Additionally, efficient control of the sludge balance and sludge age with AC drives reduces energy consumption. It also increases the amount of carbon to the digester, which can then produce more gas that can be used for energy production.

The most advanced facilities are therefore able to both clean the wastewater to a very high level and at the same time produce surplus amounts of energy. A precondition for this is normally a fully computer-controlled facility where it’s possible, via installation of AC drives on more or less all rotating equipment, to regulate all parameters.

Industrial water and wastewater

The importance of a clean and stable water supply as well as taking advantage of opportunities to make major cost reductions on the wastewater-handling side has been realized by many industries. Some industries are even moving towards a zero, or very close to zero, water use. On the clean water side, this requires utilization of advanced water treatment technologies such as RO and ultrafiltration. The VLT® AQUA Drive helps improve process reliability and reduce operation costs. On the wastewater handling side, the trend is similar to the municipalities’ vision; wastewater should be seen as a resource from which energy and other resources can be obtained.

Generating surplus power from wastewater treatment

Since 2010, Marselisborg wastewater treatment plant has transformed its focus beyond minimising energy consumed, to maximising net energy surplus. Nowadays the facility has net production of both electricity and heat, supplying the district heating system in Denmark’s second-largest municipality, Aarhus. The carbon footprint has been reduced by 35 % accordingly.

Contact us

For further information please contact us

Case studies

-

if (isSmallPicture) {

Full-scale biogas plant in Kalundborg ensures the return of all nutrients back to nature

Full-scale biogas plant in Kalundborg ensures the return of all nutrients back to natureAC drives from Danfoss help convert biomass from insulin and enzyme production to energy.

-

if (isSmallPicture) {

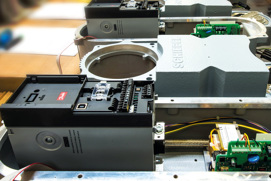

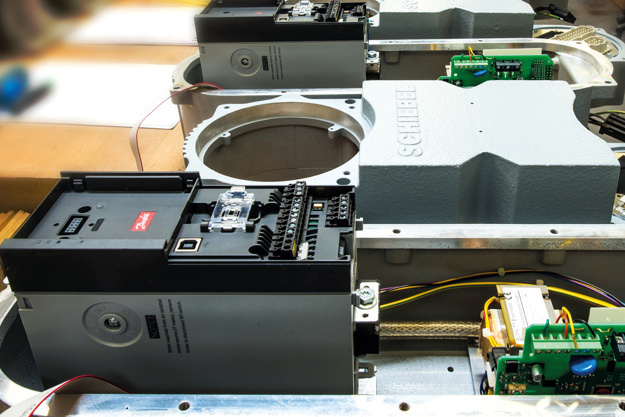

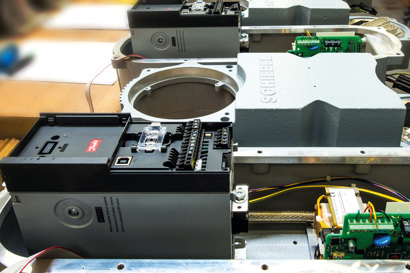

VLT® Midi Drive for precise actuator control

VLT® Midi Drive for precise actuator controlWith its compact and temperature-resistant design, the drive integrates easily into actuators from Schiebel Antriebstechnik GmbH, providing high-precision flow control.

-

if (isSmallPicture) {

Ferrari racetrack hydro system performs exceptionally

Ferrari racetrack hydro system performs exceptionallyVLT® AQUA Drive FC 202 with IP66 protection provides fast and accurate control of pump pressure for essential aquaplaning tests.

-

if (isSmallPicture) {

Cool savings for pool pumps

Cool savings for pool pumpsBy controlling the motor in a pool, VACON® 20 Cold Plate can achieve energy savings of up to 70%.

-

if (isSmallPicture) {

Improved water pumping in Kristinestad

Improved water pumping in KristinestadVACON® 100 FLOW provides even flow and reduces pressure spikes in the water supply in the west coast of Finland.

-

if (isSmallPicture) {

‘Green’ desalination in Cafoeidian

‘Green’ desalination in CafoeidianHigh efficiency and the necessary pressure required for the process to yield the best results are achieved by using VLT® AQUA Drives on all pumps in the plant.

Products

-

if (isSmallPicture) {

VACON® 100 FLOW

VACON® 100 FLOWDedicated functionality that improves flow control and saves energy in industrial pump and fan applications.

-

if (isSmallPicture) {

VLT® AQUA Drive FC 202

VLT® AQUA Drive FC 202VLT® AQUA Drive FC 202 controls all types of pumps and comes equipped with a cascade controller.