Let’s built it better

The energy crisis, decarbonization goals, and evolving regulations are hastening the shift to green energy in domestic, commercial, and industrial heating. Hydronic heat pumps are playing a central role in this sustainability-driven journey. Danfoss is your trusted partner, offering a comprehensive solution. From heat source to distribution, we provide an extensive portfolio, application expertise, and market-leading simulation and testing capabilities. We support OEMs in systems’ design and co-design, across various regions and applications, and we help installers ensure proper installation and hydronic balancing, optimizing energy efficiency and cost savings.

Features and benefits

Accelerated time to market with 97% accurate simulation results and lab-testing

Simplified manufacturing through integrated modular systems

Diverse compressor technology portfolio for various heat pump types, from domestic to large high temperature systems

Comprehensive cooling and heating solutions, from heat source to hydronic distribution

AI-based Leanheat services for optimized performance and reduced energy costs

Expert heat pump team for specification, simulation, and testing

Strong local and global presence and support

Solutions for residential and commercial hydronic heat pumps

Residential heating: greener heating for houses, from source to distribution

Our comprehensive R290 offering accounts for more than half of the bill of materials (BOM) value for a typical A/W residential heat pump—from the rotary and drive compressor package to the gas detector and the universal controller—streamlining design processes, reducing sourcing complexity, and accelerating time to market. When integrated with our hydronic portfolio, we provide the most efficient heating architecture, enabling homeowners to manage energy usage and costs effectively. Enhancing the energy efficiency of single-family homes is a crucial step toward decarbonization.

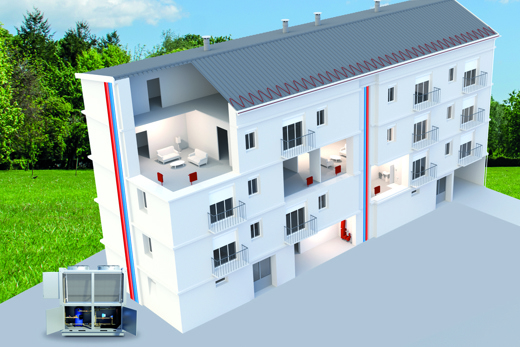

Commercial heating: greener heating for buildings, from source to distribution

Ensure year-round efficiency with our comprehensive R290 offering, encompassing compressors, heat exchangers, electronic controllers, valves, controls, gas detectors, and sensors. Attain lower supply temperatures and enhanced efficiency through our variable speed compressor paired with a brand-new HVAC drive, capable of delivering water temperatures up to 80 °C. When integrated with our hydronic portfolio, eliminate pressure and flow deviations to achieve effective performance in both full- and part-load conditions. Enable lower supply and return temperatures for a sustainable heating solution.

Commercial heating: climate-friendly heating for buildings, from source to distribution

The multi-refrigerant component portfolio, encompassing compressors, heat exchangers, valves, controls, gas detectors, and sensors for R454B/R32, offers ultimate flexibility for system design and competitive applied costs. The PSH scroll compressor, featuring innovative liquid injection technology dedicated to A/A and A/W heat pumps in cooler climates, enables heating water up to 150°F at ambient temperatures as low as -5°F. When paired with our hydronic portfolio, it enhances overall building performance with a sustainable heating architecture.

Solutions for commercial and industrial heat pumps

Up to 100°C water temperature, with low-GWP HFC, HFO, and natural refrigerants

Above 100°C water temperature

The SuPrHeat Project

The project "SuPrHeat—Sustainable process heating with high-temperature heat pumps using natural refrigerants is an interdisciplinary and cross-cutting research, development, and demonstration project with 16 partners from Denmark, Germany, UK and Sweden.

Achievement: a 500 kW HTHP operational at DTI, built on the following specifications

- A pentane/butane cascade system, capable of achieving a maximum condensing temperature of 150°C

- The system integrates Danfoss industrial refrigeration components and BOCK® compressors featuring cylinder cooling and special oil

- Project partners plate heat exchangers and controllers

- The project is containerized, eliminating ATEX zone requirements

If you are interested in co-development projects or for an introduction to our solutions, get in touch.

Learn more at: About the Project

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| Article | DKRA.PE.100.A2.22 _Smart_Energy_Systems_MS | English | Multiple | 14 May, 2018 | 756.0 KB | |

| Brochure | DKRCC.PB.001.F5.01_HeatPumpSolution_Brochure | Danish | Multiple | 22 Oct, 2018 | 1.8 MB | |

| Brochure | DKRCC.PB.001.F5.07_HeatpumpsSolution_Brochure | Swedish | Multiple | 23 Oct, 2018 | 1.7 MB | |

| Brochure | DKRCC.PB.001.F5.20_HeatPumpSolution_Brochure | Finnish | Multiple | 23 Oct, 2018 | 1.8 MB | |

| Brochure | DKRCC.PB.001.F5.22_HeatPumpSolution_Brochure | English | Multiple | 19 Mar, 2018 | 3.0 MB |

Case studies

Discover cases and insights

Policies and regulations impacting the heat pumps design and their implementation

Refrigerants and energy efficiency

We know refrigerants and Ecodesign. Visit our hub to stay up-to-date on regulations and trends, download our white paper or our low-GWP ebook, get your questions answered with our useful FAQs, and learn with our training courses and videos.

Evolving regulations accelerating the phase out of fossil fuels

Experts’ reports and information on heat pumps

- The Future of Heat Pumps – Analysis – IEA

- Is the energy crisis really making the business case for heat pumps? – Analysis – IEA

- Heat pumps action plan: online consultation launched by Commission to accelerate roll-out across EU (europa.eu)

- European Heat Pump Association – Renewable energy (ehpa.org)

From heat pumps to district heating, read our expert paper

Bridging the demand and supply side of energy, this paper summarizes the main avenues towards decarbonization with a view to supporting the EU’s and global energy and climate goals.

Related applications

-

if (isSmallPicture) {

Oil-free solutions

Oil-free solutionsToday’s HVAC systems have high demands. HVAC systems are not only required to meet energy and performance standards but also provide building owners with exceptional benefits.

Support

Application diagram - heat pump components in typical A/C system

Key for application diagram:

- Compressor

- Controller

- Four-way valve

- Temperature sensor

- Pressure sensor

- Cartridge pressure control

- Evaporator

- Condenser

- Temperature sensor

- Expansion device

- Sight glass

- Liquid line filter drier

Learning

Learn more about heat pumps with Danfoss' eLearning courses. Follow the links below and sign-up to take the courses today.

Courses on air conditioning heat pumps

Learning

Resources and training

News

-

if (isSmallPicture) {

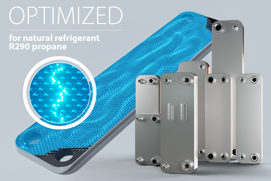

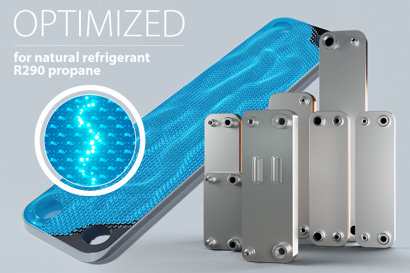

Optimized R290 brazed plate heat exchangers: Lower charge and higher heat transferMonday, 30 September 2024

Optimized R290 brazed plate heat exchangers: Lower charge and higher heat transferMonday, 30 September 2024Growing our already extensive brazed plate heat exchanger portfolio we proudly unveil our latest innovations featuring Micro Plate™ technology.

-

if (isSmallPicture) {

New generation conversion tool for discontinued productsThursday, 22 June 2023

New generation conversion tool for discontinued productsThursday, 22 June 2023The DrivePro® Retrofit conversion tool helps you to find the most suitable successor drive.

-

if (isSmallPicture) {

Reduce energy consumption and go green with the Danfoss Heat Recovery UnitMonday, 4 April 2022

Reduce energy consumption and go green with the Danfoss Heat Recovery UnitMonday, 4 April 2022The focus on cutting energy consumption and reducing the carbon footprint has never been greater, but results are often achieved by compromising usability or efficiency. The Danfoss Heat Recovery Unit delivers strong environmental benefits as well as significant reductions on heating bills—all delivered with a short ROI.

Contact us

Meet our hydronic heat pump experts

Specifications, standards, simulations, and testing capabilities: an unmatched combination of expertise and tools

Application Development Centers

The Danfoss global Application Development Centers (ADCs) offer you expert support and state-of-the-art test facilities for your business. Partner with our experts to develop and improve your HVAC-R systems at our facilities located in Denmark, India, China, and the United States.

The A3S service—Advanced System Simulation Services

- Accelerate time to market: reduce development time and lab testing

- Save on development costs: save on resources—people and lab capacity

- Optimize systems: capacity, efficiency and charge with a multi-component approach

- Secure investment: check component selection operating maps

Virtual system solutions

Our tools and virtual system solutions using Modeling & Simulation, Data Analytics, Digital Twins, and Software Development support our customers in making the right choices when it comes to system designs.