Integrated CBM in one comprehensive package

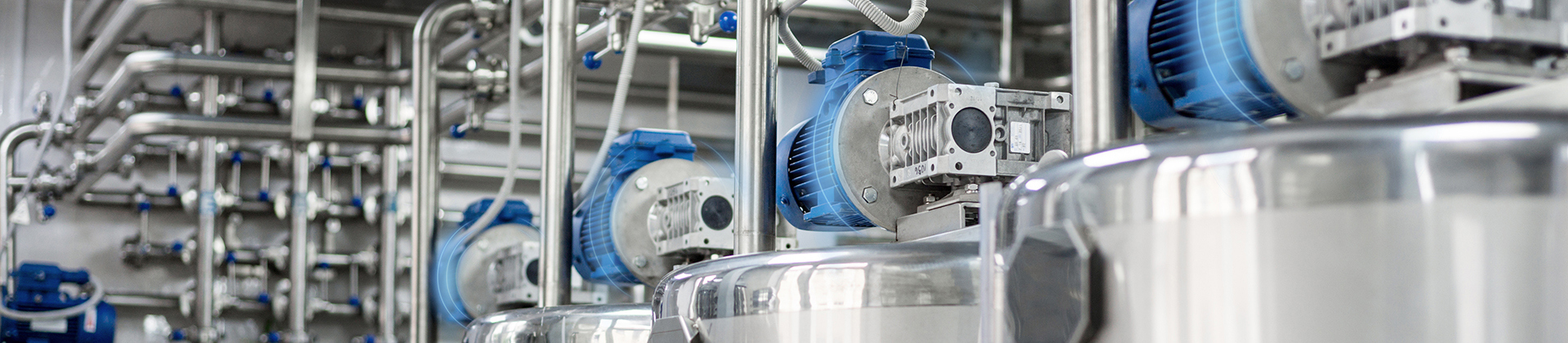

Condition-based monitoring (CBM) integrated into premium Danfoss drives has revolutionized the way these drives monitor electric motors for faults and potential failures. With breakthrough technology implemented at the drive level, CBM offers advanced features such as motor stator winding monitoring, vibration monitoring, wear-out monitoring of bearings, load envelope (torque) monitoring, and cavitation detection, all in one comprehensive package.

CBM is especially suitable for remote locations or devices that are difficult to access. With permanent monitoring, potential faults can be detected and addressed before they result in motor failure and production downtime. By taking maintenance strategies to the next level with CBM, industries can increase their application uptime, reduce maintenance costs, and enhance overall operational efficiency.

More about remote monitoring

Highlighted products

Danfoss first innovations

CBM has emerged from a history of Danfoss firsts in innovation. Danfoss drives differentiate from others in the market with intelligent functions embedded in the drive, to reduce the external components required.